Supporting supply chain transformations that drive economic value, business feasibility, and client and social values

Supply Chain Management

Service

Supply chain management (SCM) transformations have primarily been aimed at improving quality, costs, and delivery times. They focused on creating platforms that could support global expansion and the growth of the business. Businesses have recently elevated their supply chains to become part of the company-wide management agenda. Stakeholders are calling for changes that go beyond old ways of thinking to meet the challenges of increasing geopolitical risks, the growing responsibility of companies towards social and environmental issues, and to respond to changing client needs and business models.

ABeam Consulting is ready to support companies who are pursuing company-wide supply chain management transformations to create greater economic value, business feasibility, client value, and social value.

-

Insight

#3 ABeam Consulting shares insight on Vietnam’s pharmaceutical sectors’ opportunities, challenges, and entry approaches for New Entrants

-

Insight

Digital twins reshaping Vietnam's logistics and supply chain landscape

-

Case Study

Ajinomoto Co., Inc.:Integrating data through a use-case-driven approach Fostering data utilization across the Group to accelerate business value creation

-

Insight

Realizing resilient and sustainable procurement strategies and improving procurement area productivity using AI

-

Case Study

Panasonic Energy (Thailand) Co., Ltd.:Establishing the integrated supply chain management process from sales to production and optimizing inventory across the entire supply chain

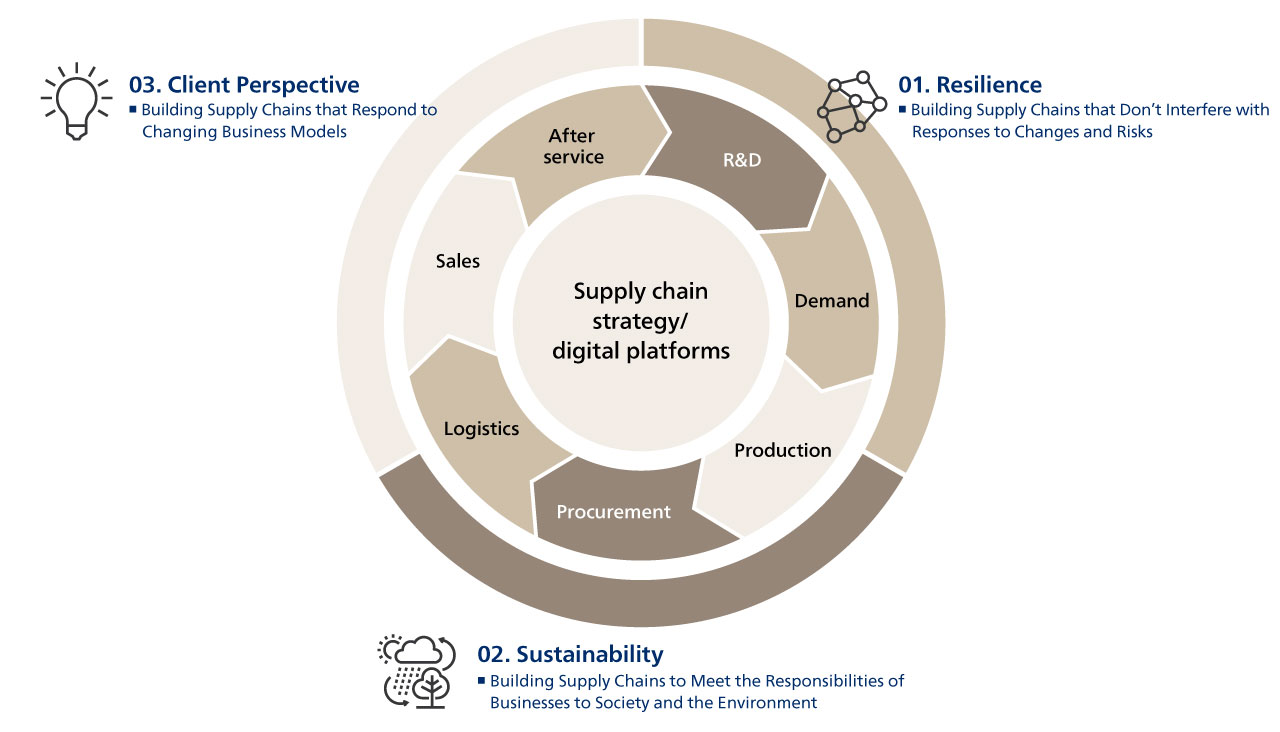

Trends/Challenges

Building supply chains that don’t interfere with responses to changes and risks

Supply chains are exposed to unprecedented levels of risk due to global demand imbalances caused by the pandemic, fragmentation of supply chains due to conflicts between nations, competition in semiconductor procurement, global logistics issues caused by container shortages and delays, and suspended plants caused by cyberattacks and natural disasters. Many of these things happen without warning and can have severe effects on supply chains and businesses.

Businesses must account for critical supply chain risks that could render them unable to “buy, make, transport, or sell.”

Improving supply chain resilience requires bold initiatives at the company management level. Companies must fundamentally reorganize existing supply chains by increasing their depth and redundancy (multi-plant strategy), reorganizing to facilitate rapid responses to incidents, and real-time visualization of operational statuses and inventories.

Building supply chains for changing business models

Recent technological advances are forcing major transformations in company business models. Companies must now meet client needs from many different angles. They must make customer-oriented transformations to meet these needs, even in the supply chains that serve as the source of their competitive power.

Companies must optimize their existing supply chains to establish business models that respond to changes in the way products and services are provided (subscription models, sharing economies, service-led businesses, or customer support) and the way that logistics are carried out (multi-channel, direct sales, customizable production systems, individualized management). These transformations go beyond manufacturing frameworks and operational processes, requiring redesigns and reconstruction of locations and supply networks.

We are also witnessing a rapid rise in risks concerning the feasibility of supplying products and services. This risk is caused by increases in the volume of goods being shipped, logistics personnel shortages, and changes in major business trends. How to balance feasibility with improving services is a major management challenge.

Building supply chains to meet the responsibilities of businesses to society and the environment

Stakeholders are calling for corporate responsibility and information disclosures regarding social and environmental issues. Companies are expected to take responsibility and contribute to society by cooperating with stakeholders in and beyond their supply chains.

Companies must go beyond their existing management imperatives of “quality, cost, delivery,” and focus on the sustainability of their supply chains, the “environmental side” of reducing CO2 emissions and cutting waste, and the “ethical side” of avoiding conflict mining and human rights risks. For these reasons, companies are advancing initiatives to better visualize new information, working with other businesses to revise their manufacturing processes, building traceability into procurement, production, and transportation processes, establishing reverse supply chains that support recycling, and ensuring procurement process transparency.

Europe and the automotive industry are building inter-company platforms and making regulatory moves, providing leading examples of sustainable supply chains. The time has come for all companies to cooperate and address these challenges.

Where ABeam Stands Out

-

Japan’s leading supply chain specialists

ABeam specialists have extensive experience in the supply chain and engineering domains and are driving transformation across numerous companies. ABeam is ready to support your transformation with a team of cross-domain experts.

-

Knowledge developed over 40 years of global supply chain transformations

Since ABeam’s founding over 40 years ago, we have earned a track record of building global supply and engineering chains centered on companies in Asia and deploying them around the world. We have been able to develop our unique methodology based on our advanced benchmarking and case studies.

-

End-to-end support, from design and implementation of supply chain transformations to value creation

ABeam works with clients to take a leading role in involving stakeholders, implementing business transformations, improving operational processes and systems, and creating value.

Services Provided

ABeam Consulting has an extensive track record of providing end-to-end services focused on achieving management goals by transforming supply chain management for businesses around the world and working closely with the people on the ground.

Supporting the formulation of a supply chain strategy

-

Supply Chain Reform Level Diagnostic Program (Japanese)

-

Supply Chain Redesign and Process Transformation Support Service using Digital (Japanese)

-

FTA & EPA Utilization Support Service (Japanese)

-

Support Service to Formulate Logistics DX Vision (Japanese)

-

Facilities Maintenance Management Diagnostics (Japanese)

-

Short-Term Indirect Materials Purchasing Cost Reduction Service (Japanese)

Supporting operational transformation

-

Supply and Demand Operation BPR (Japanese)

-

Indirect Material Cost Management Support (Japanese)

-

Support Service to formulate Robotization and Automation Vision for Logistics Center (Japanese)

-

Cost Planning Services for Manufacturing that Creates New Perspectives for Cost Optimization

-

Resilient and Sustainable Procurement Strategy Formulation Support Service (Japanese)

Supporting the development of digital platforms

-

ABeam Supply and Demand Cloud Service (Japanese)

-

Simulator for Logistics Centers: ABeam Cloud® Warehouse Simulator by WITNESS (Japanese)

-

Source-to-Pay Cloud Platform Implementation and Utilization Support Service (Japanese)

-

SAP S/4HANA® Quick Supplier Portal

-

Digital Transformation Support Service in Transportation and Delivery (Japanese)

-

Implementation Service for Integrated Business Planning (IBP)

-

Logistics Center DX Support Service Using Warehousing Execution Systems (WES) (Japanese)

-

Data-driven Process Optimization for Operational Excellence

Case Studies

-

Ajinomoto Co., Inc.

Integrating data through a use-case-driven approach Fostering data utilization across the Group to accelerate business value creation

-

Panasonic Energy (Thailand) Co., Ltd.

Establishing the integrated supply chain management process from sales to production and optimizing inventory across the entire supply chain

-

Alps Alpine Co., Ltd.

Global One Instance mission critical system Promoting DX based on Globally Unified Data Platform

-

TOSTEM THAI CO., LTD.

Data-driven issue assessment through process mining and surveys

Click here for inquiries and consultations