In the manufacturing industry, accidents and incidents such as recalls arising from product incidents, factory fires, and occupational accidents occur constantly, making prevention an urgent issue. We think that one of the main causes is human error caused by insufficient investigation and consideration before task execution or during equipment/machinery design. While accumulated knowledge about operations (in this Insight, digitized text data) exists both inside and outside a company, this knowledge cannot be fully utilized due to its vast quantity and the scattered state of the knowledge necessary to derive solutions.

As a solution, the use of large language models (LLMs) trained on internal and external knowledge can be considered. While LLMs appear to be effective, few companies are currently using LLM systems trained on specific data. This is because use cases specific to the company and concrete benefits are unclear.

ABeam Consulting, in collaboration with Professor Yotaro Hatamura, Professor Emeritus at the University of Tokyo and a leading expert in failure studies, has developed an LLM system called "Failure Studies Consultant." This system has been trained on failure studies data with the aim of providing companies with an environment to explore use cases and verify the effectiveness in preventing accidents and incidents (currently available free of charge for a limited time, details below). When questions about operational precautions are posed to the "Failure Studies Consultant," users can gain insights about potential failures. Furthermore, by inputting additional company-specific knowledge, it is possible to build an LLM system that can provide advice surpassing that of experienced employees. Such a system can greatly contribute to the prevention of accidents and incidents and support the creation of new value.

This Insight page summarizes the utilization of LLM systems as a preventive measure based on the current state of accidents and incidents in the manufacturing industry.

Creating the “eternal experienced employee” with large scale language models ~Advanced utilization of failure studies and internal knowledge to prevent accidents and incidents in the manufacturing industry~

- DX

- AI

Trends in manufacturing accidents and incidents and their causes

Manufacturing accidents and incidents never go away

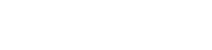

In the manufacturing industry, a significant problem is the occurrence of human casualties, such as death and injury, and financial losses, such as equipment damage, lost production opportunities, and product recoveries, resulting from product incidents related to automobiles, electrical appliances, and the like, or fires, leakage, and occupational accidents at factories and plants. As an example, Figure 1 shows the trends of fire and leakage accidents at hazardous material facilities. In this figure, hazardous materials refer to substances with flammable or ignitable properties (such as gasoline, kerosene, and oil-based paints), which are subject to legal regulations for production and storage. Even at hazardous material facilities where strict management is required, the number of fire and leakage accidents per facility is trending upward, indicating that accident and incident prevention is an urgent issue.

Figure 1 Trends in fire and leakage accidents per 10,000 hazardous material facilities

Figure 1 Trends in fire and leakage accidents per 10,000 hazardous material facilities

Source: Fire and Disaster Management Agency “Overview of Accidents Involving Hazardous Materials in 2022 ”

Human error due to insufficient investigation and consideration before task execution or during equipment/machinery design

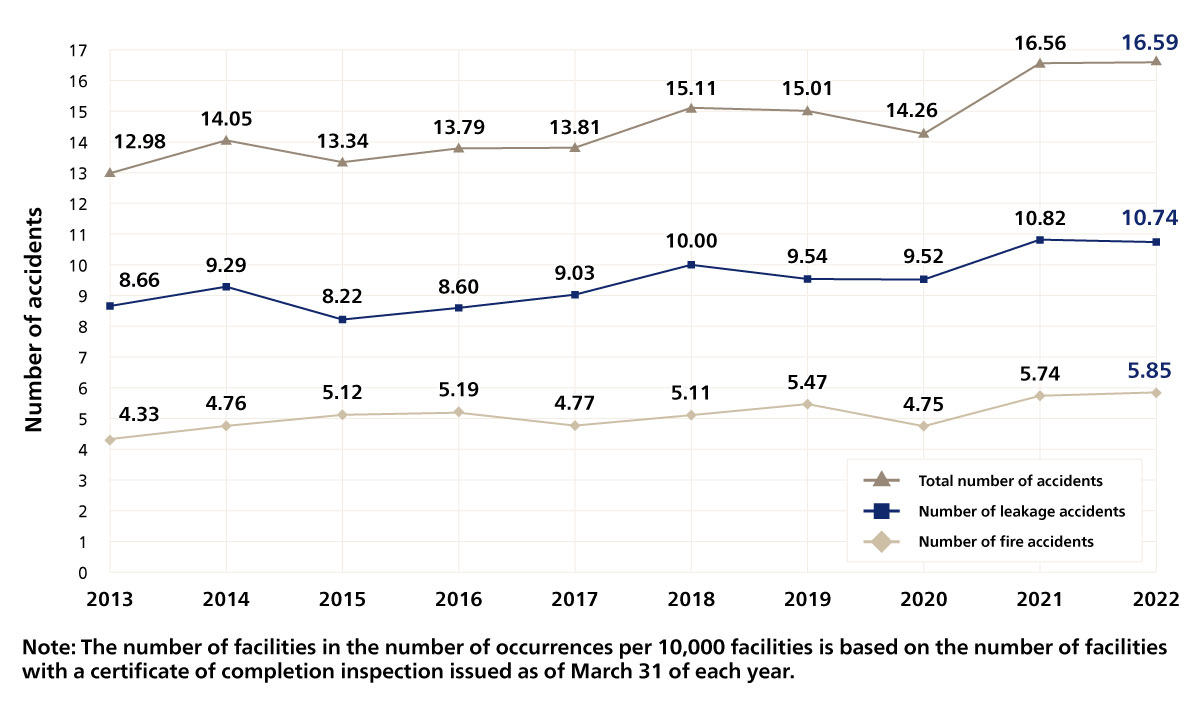

As shown in Figure 2, the majority of fire and leakage accidents in hazardous material facilities are caused by human errors (insufficient operation verification, maintenance and monitoring; failure to perform operations; incorrect operation; poor design/construction, etc.). Even for deterioration such as corrosion fatigue, damage, and failure, which are classified as equipment failures, occurrence can be suppressed through human management, and is therefore considered in part to be caused by human error (such as insufficient management). Here, we will discuss the causes of human error. One of the main causes is thought to be insufficient investigation and consideration before task execution or during equipment/machinery design. Checking manuals and past KY (hazard prediction) activities before task execution and gaining an understanding of the work content and hazardous locations improve task reliability. Further, in equipment and machinery design work, referencing past similar design review documents, change management review documents (documents for identifying risks when changing equipment or operations), and related incident cases can reveal items that should be considered, preventing design mistakes. In this way, investigating and considering various knowledge such as manuals, design review documents, change management review documents, and incident cause analysis materials should lead to the prevention of human error.

Figure 2 Factors causing accidents at hazardous material facilities in 2022 (left: fire, right: leakage)

Figure 2 Factors causing accidents at hazardous material facilities in 2022 (left: fire, right: leakage)

Source: Fire and Disaster Management Agency “Overview of Accidents Involving Hazardous Materials in 2022”

Internal and external knowledge cannot be fully utilized

On the other hand, it is inferred that while accumulated knowledge about operations exists both inside and outside a company, presumably this knowledge cannot be fully utilized due to its vast quantity and the scattered state of the knowledge necessary to derive solutions. Although it is possible to keyword search for knowledge that seems relevant to the task or equipment/machinery design to be executed, the workload is significant as it requires reading each piece of found knowledge and confirming whether there is any relevant information. As a result, without the outcomes of detailed investigations conducted by others in the past being utilized, a great deal of time is spent on similar investigations, and the possibility exists that similar problems will occur. Until now, in many cases, experienced workers within the company would remember past knowledge and provide advice as appropriate, but such talent is retiring in association with the aging of our population, making effective utilization of dormant knowledge both inside and outside the company essential to maintain and improve operational quality in the future.

Utilizing knowledge based on large scale language models

What can be achieved with large scale language models?

As means for effectively utilizing knowledge, large language models (LLM), which gained attention through ChatGPT, have emerged. A large language model is AI that has learned vast amounts of text data on the Internet, enabling text generation, summarization, translation, and information provision through high analytical capabilities and natural language processing abilities.

While conventional large language models can be utilized for general tasks, they lack company-specific knowledge such as internal documents, making it difficult to provide appropriate advice with respect to company-specific operations.

In response, we constructed an LLM system tailored to company-specific operations by utilizing retrieval-augmented generation (RAG) technology, which enhances generation capabilities through searches, and inputting specific data (knowledge) into the LLM system. This technology enables the presentation of information suitable for company-specific operations as text, drawn from vast amounts of internal and external knowledge.

Introduction challenge: Company-specific use cases and benefits unclear

The construction of an LLM system learned on specific data is considered to be technically feasible and effective, but there are not many companies that are currently taking advantage of such a system. The reason for this is that companies have not experienced a RAG-based LLM system, are unclear with regard to use cases within their own company and the specific benefits that could be gained, and are not at the stage of investigating introduction.

Failure studies x large scale language models = failure studies consultant

As one way of overcoming this introduction challenge, ABeam Consulting, in collaboration with Dr. Yotaro Hatamura, a leading expert in the field of failure studies, developed an LLM system learned on failure studies data, and verified its effectiveness.

Advanced application of failure studies

Failure studies is an academic discipline that investigates the causes of accidents and failures, providing strategies to prevent accidents and failures that could result in economic damage or loss of life. A distinctive feature of the failure studies field is the focus on analyzing human factors, separate from physical cause analysis and phenomenon investigations typically conducted in accident and incident analysis. When a failure event occurs, this field analyzes the relationship between human "failure behaviors and motivational causes" and the "failure event," generalizing (turning into knowledge) these relationships. The field advocates applying this generalized knowledge to different tasks or across different occupations to anticipate potential failures that have not yet occurred and develop preventive measures. From the perspective of accident and incident prevention, many manufacturing companies are already utilizing failure studies. In this project, we thought that by inputting failure studies knowledge into the LLM system, failure studies could be utilized more sophisticatedly by pinpointing ideas for users, which would help them prevent accidents and problems.

Effectiveness of “Failure Studies Consultant”

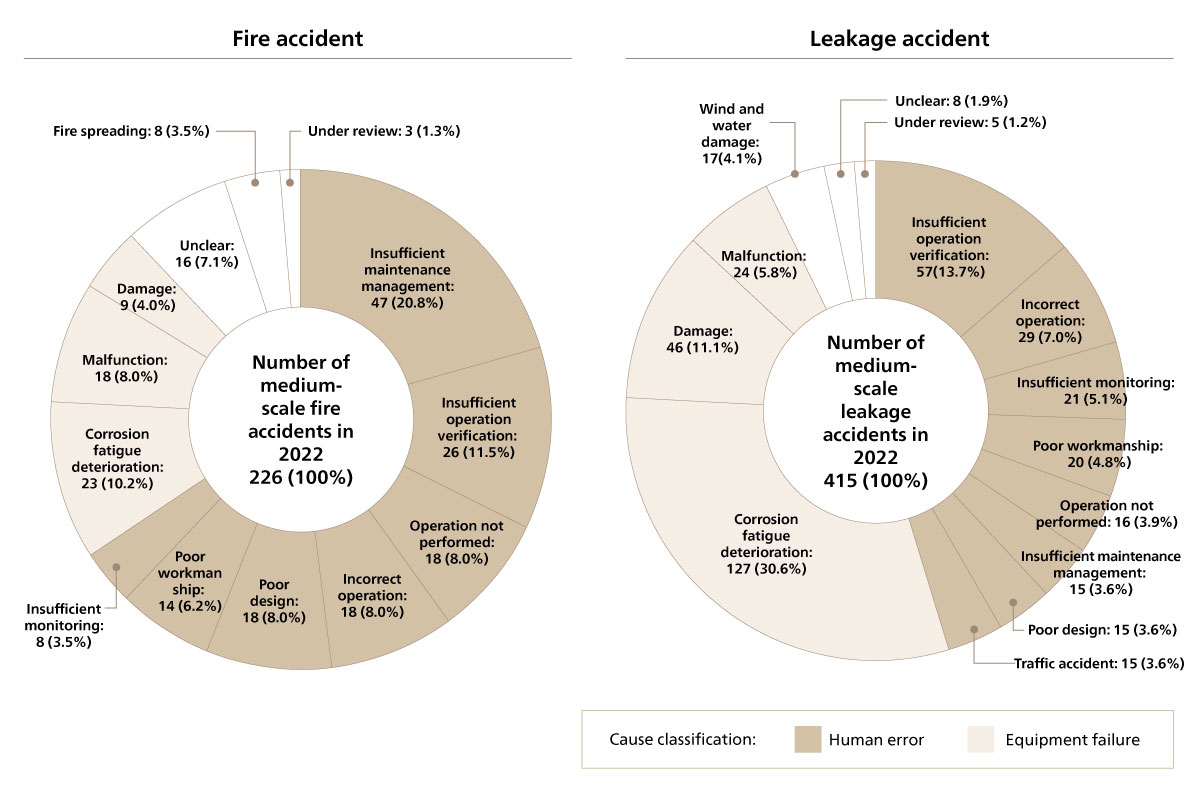

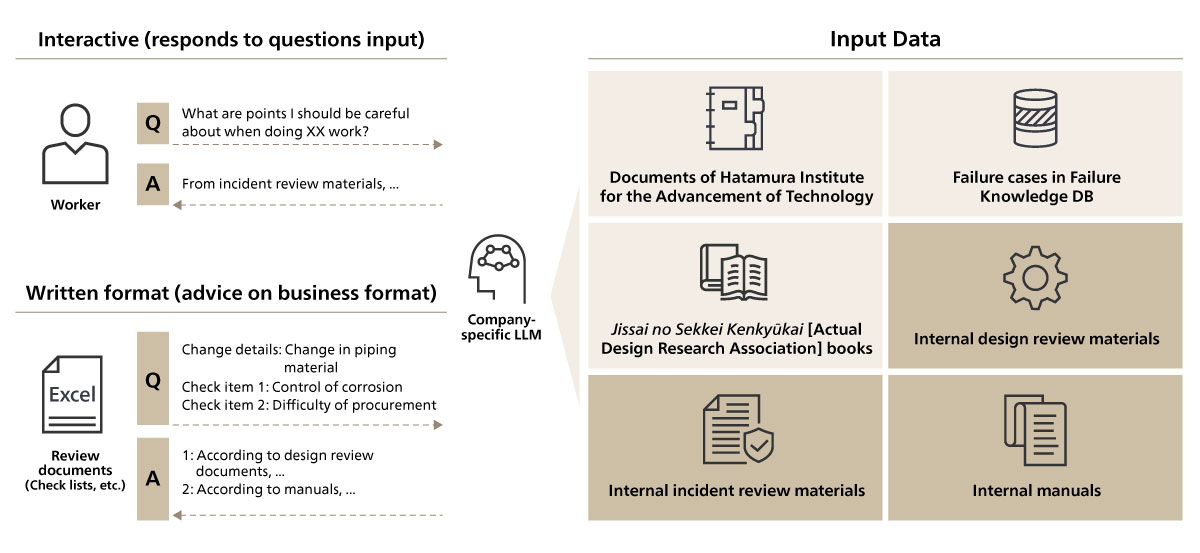

The LLM input data consisted of literature including books and reports from the Hatamura Institute for the Advancement of Technology, Failure Knowledge Database owned by the Association for the Study of Failure (NPO), and the "Jissai no Sekkei [Actual Design]” book series owned by the Jissai no Sekkei Kenkyūkai [Actual Design Research Association]. In response to queries about specific task precautions, conventional LLM systems only provide general responses (such as "Be careful about safety"). The "Failure Studies Consultant," however, is a powerful solution that can extract appropriate information from vast failure studies knowledge, and provides pinpoint advice on task precautions based on failure studies insights and similar failure cases, along with links to case examples. Additionally, the Failure Study Consultant demonstrates behavior close to “turning failure studies into knowledge" by extracting commonalities from failure cases across different industries to provide advice.

Figure 3: Overview of “Failure Analysis Consultant” (use case: plant equipment modification investigation)

Figure 3: Overview of “Failure Analysis Consultant” (use case: plant equipment modification investigation)

Internal knowledge x large scale language model = eternal experienced employee

Furthermore, using the “Failure Studies Consultant” as a starting point, an LLM system specialized in internal operations can be built by incorporating internal knowledge such as manuals, incident cause review materials, design review documents, and change management review documents. By questioning a company-specific LLM system about concerns and points to consider before equipment/machine design or task execution, one can instantly obtain advice that is more valuable than the experiential knowledge of experienced employees who know everything there is to know. As further development, we are considering not only enabling interactive responses but also linking the LLM system with business formats (such as Excel) so that users can automatically obtain reviews and advice on studied content described in a business format. While user examination based on responses obtained is essential, comprehensive advice is expected to prevent design and operational errors caused by insufficient consideration and investigation.

In addition, a company-specific LLM system can be used not only to solve problems such as preventing accidents and incidents, but also support the creation of new value. For example, by inputting reports on improvement activities such as production efficiency and labor-saving measures implemented at each business site into the LLM system, it is possible to obtain hints for improvement activities that are common to the entire company, which leads to improvements in profitability and labor-saving measures.

As LLM systems are expected to be utilized for solving corporate challenges and creating new value, and the advancement of LLM systems is predicted to continue, we believe the consideration of business processes and data accumulation methods with the premise of utilizing LLM systems will become essential for the manufacturing industry.

Figure 4: Overview of company-specific LLM system

Figure 4: Overview of company-specific LLM system

ABeam Consulting is providing the “Failure Studies Consultant” free of charge (for a limited time, with no need for new environment development on the user company's side) to verify use cases with many companies and expand the scope of utilization. By actually experiencing the system, companies can clarify what is possible with an LLM system that has specific data input and identify potential use cases for their own company. We hope business representatives who are interested will take advantage of this service.

ABeam Consulting will continue to aim to contribute to solving social and client challenges by promoting the use of various cutting-edge technologies, including LLM systems.

Click here for inquiries and consultations