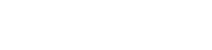

The platform is a solution for adapting to market fluctuations, stemming from suddenly emerging factors that have become common in the materials and chemicals manufacturing industry in recent years, more closely partnering with internal and external stakeholders, speeding up operations and realizing flexible supply and demand adjustments.

By taking advantage of cutting-edge technologies such as SFA and AI, it seeks to improve engagement through high value-added proposals to clients, while improving internal cooperation between production and sales departments and generating extra operational capacity.

Introduction, utilization, and support services of demand chain management platform for the materials and chemicals manufacturing industry

Supporting clients in combining the capacity to respond to changing environments and maintain growth by connecting operational processes across all stages of production through a single platform in a materials and chemicals manufacturing industry experiencing dramatic shifts in demand in areas such as semiconductors

The suddenly changing business environment in the materials and chemicals manufacturing industry

The environment surrounding companies is changing dramatically, with disruptions to supply chains as a result of natural disasters and conflicts, sudden inflation and fluctuations in exchange rates, economic security and environmental regulations. Let’s take the environment around companies dealing with functional materials, chief among which are semiconductors, as an example. In recent years, there have been frequent events wherein the business environment has shifted due to sudden factors, amidst a backdrop of price rises and competition for dominance between nation states due to a global shortage of semiconductors.

This has led to a renewed focus on DCM that can adapt to such an unpredictable business environment, ascertain real client demand early, and flexibly adapt to circumstances

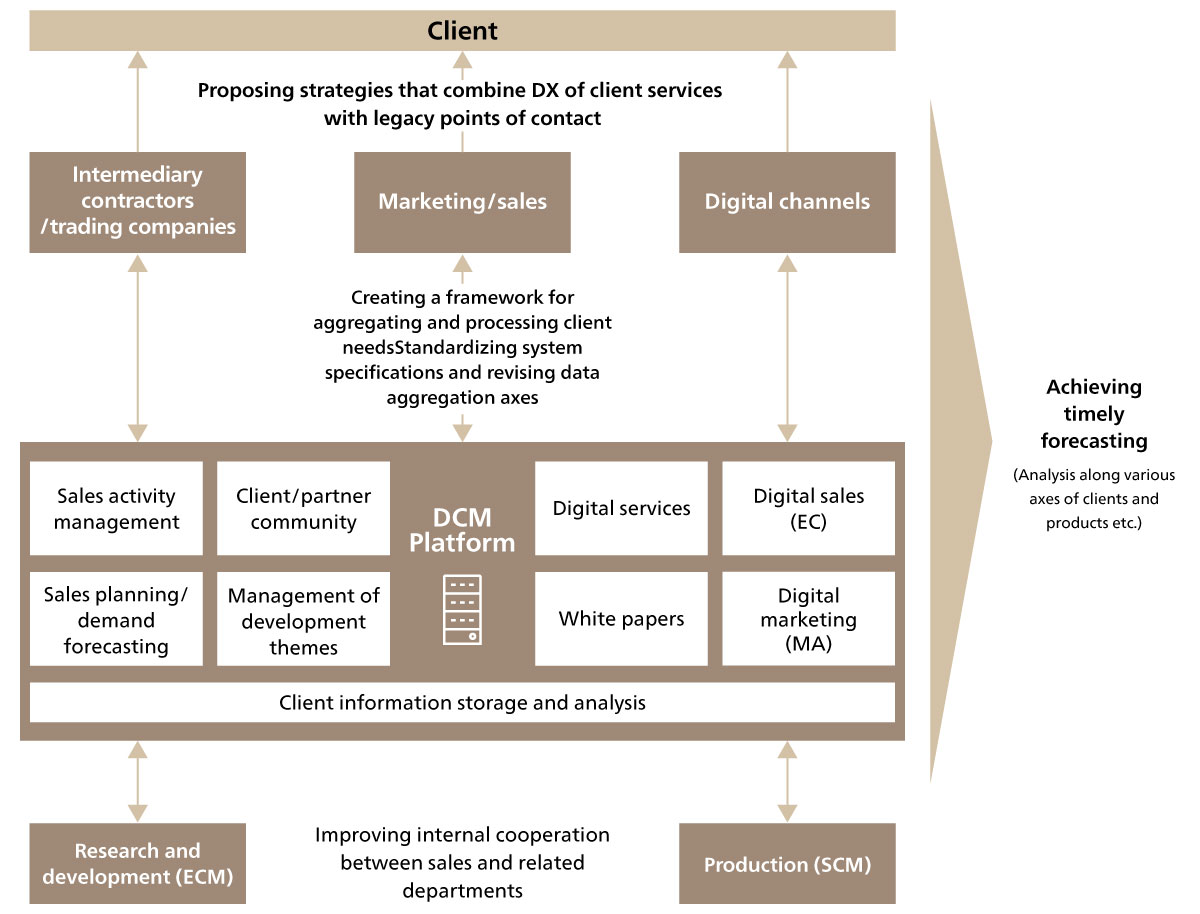

Challenges confronting materials and chemicals companies that get in the way of implementing DCM

We often see cases where issues that need to be addressed exist throughout demand chains, from working with partners such as intermediary contractors to coordinating information between internal sales and production departments. Initiatives do not proceed as anticipated.

Visualizing client behavior at intermediary contractors

Addressing the issue of manufacturers being unable to ascertain the causes behind why they have lost clients, because the series of behaviors clients engage in from visiting intermediary contractors to progressing to commercial discussions is not made available to themSpeedily handling inquiries from clients

Quickly responding to inquiries from intermediary operators about inventories, delivery times and product specifications, and thus eliminating opportunity lossesInternal standardization of data

Seeking to standardize the data sources and data granularity used by manufacturing and sales departments, and thus promote the use of data internallyStandardization of operational processes

Addressing circumstances where complexity has arisen due to differing processes between business units and products, and thus seeking to streamline operations

To meet these challenges, it is important for companies to reflect on the status of their operational reforms and systems implementations. They should then plan their future directions based on their specific characteristics, such as their various business environments or organizational structures.

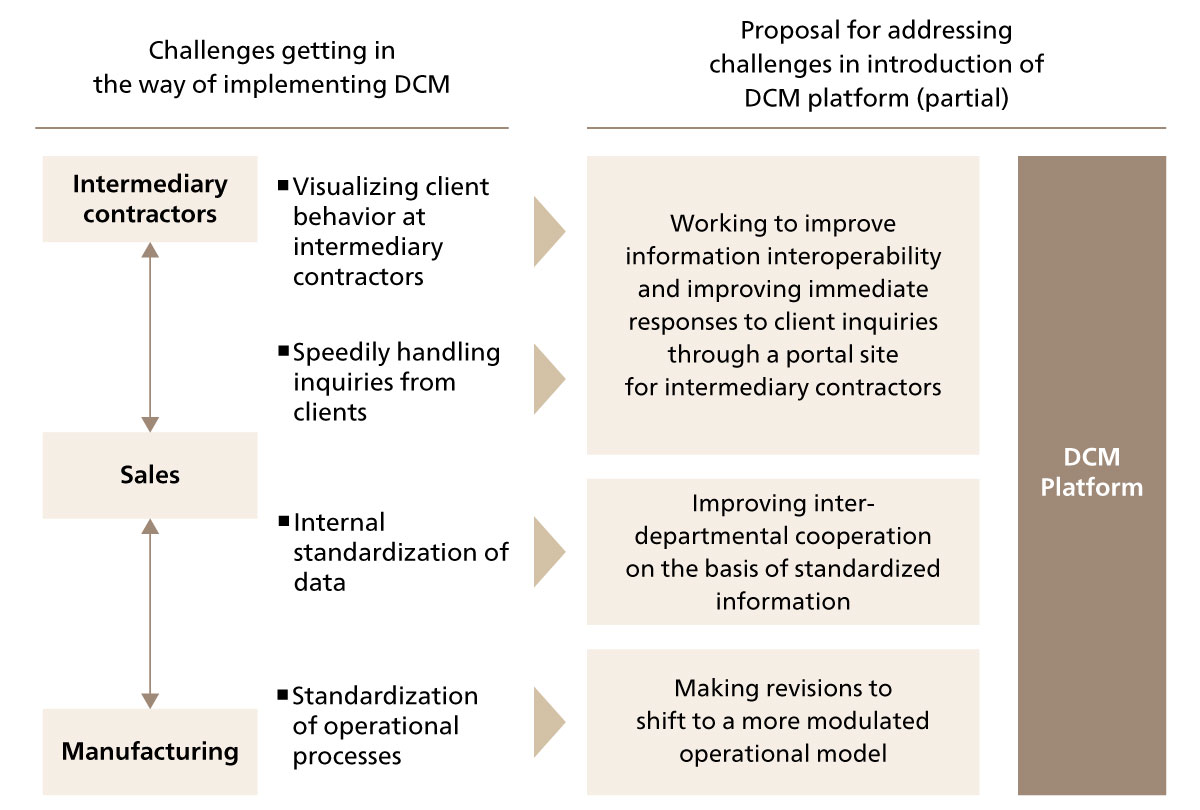

ABeam Consulting has a wealth of experience in the materials and chemicals manufacturing industry. By making use of templates and know-how that come from using real-world examples as model cases, we can help your company progress more quickly through every phase of the process, from formulating vision and strategy, to solidifying operations.

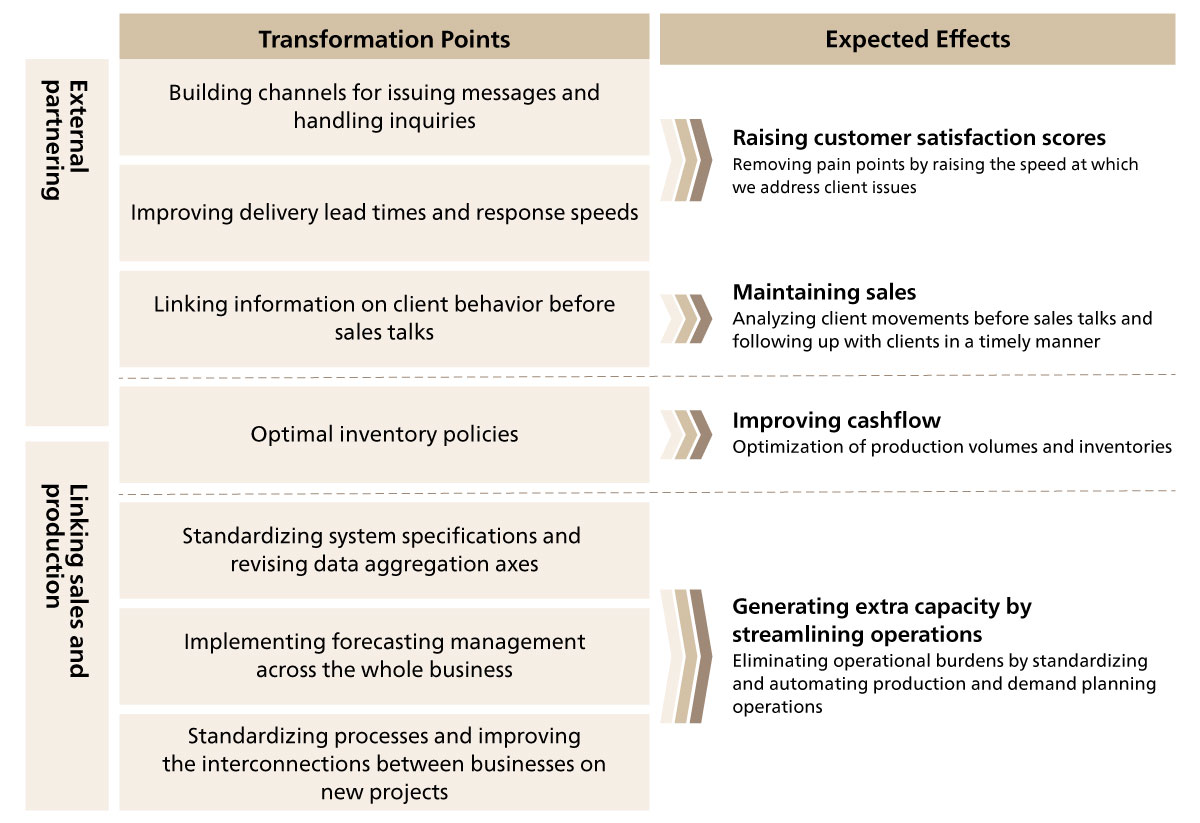

Anticipated effects of this service

By improving cooperation internal and external the company, we can maintain and expand sales through improved customer satisfaction scores, and achieve greater streamlining of operations. The keys to achieving this are external cooperation with intermediary contractors among others using portals, and internal cooperation through centralization and utilization of data.

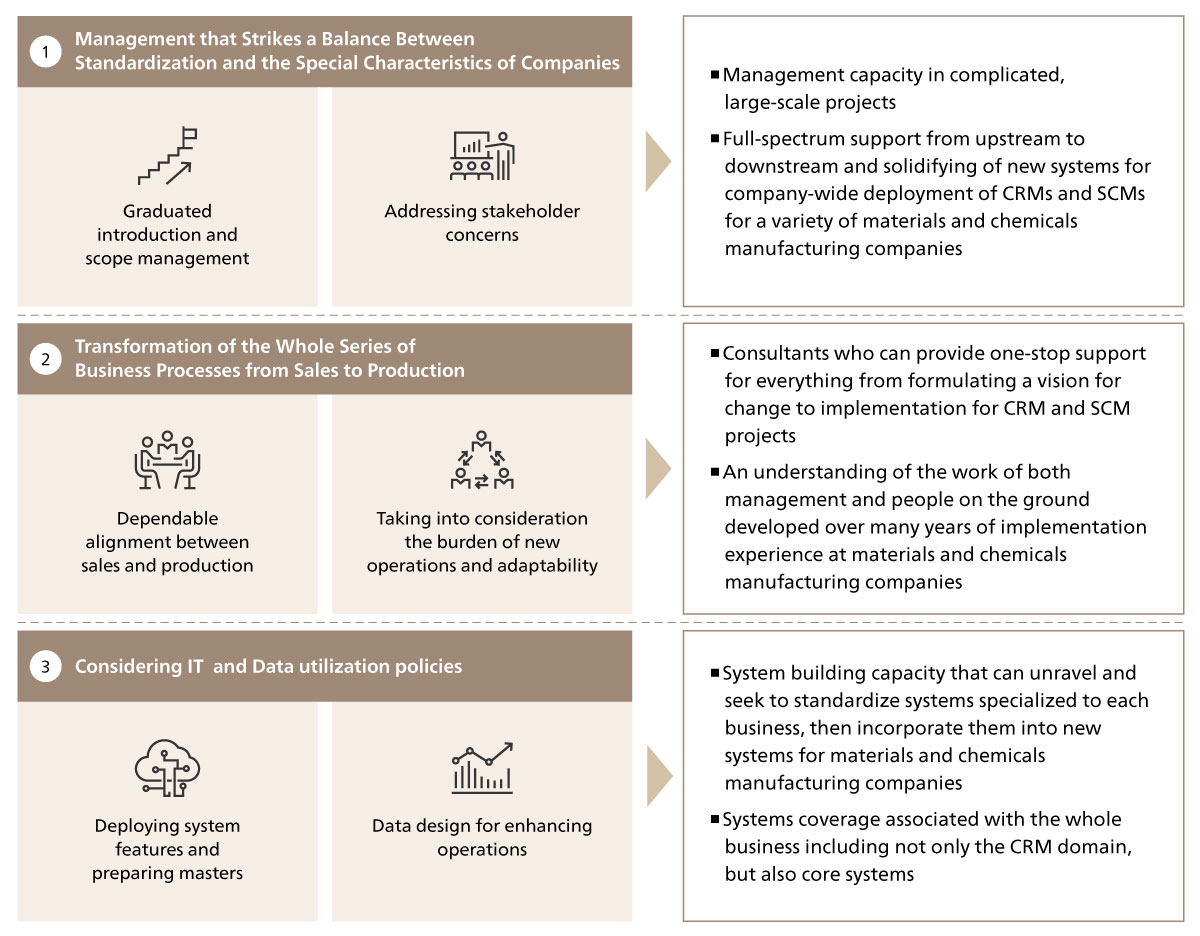

Key points for implementation (key success factors) and value provided by ABeam

ABeam consultants, who have a wealth of knowledge of the particular characteristics of the materials and chemical industry and who provide a one-stop service, combine service line and industry knowledge with cross-functional capabilities to provide this solution.

ABeam Consulting also demonstrates the vision to drive projects with a shared understanding of the issues and realize demand chain management consistently across entire companies even in circumstances where internal and external stakeholders have differing aims and speeds at which they work.

Click here for inquiries and consultations