Panasonic Energy (Thailand) Co., Ltd. boasts the No. 1 market share in the Thai domestic dry battery market.

To maximize its market share, Panasonic Energy is working to streamline sales activities together with its distributors. With ABeam Consulting’s support, Panasonic Energy integrated its supply chain management (SCM) processes across manufacturer-distributor boundaries, which had previously been managed separately by each organization, to supply the products needed in the market more timely. Panasonic Energy has thus implemented the integrated supply chain management process from sales to production starting from real market demand, driving transformation in the supply chain model.

Panasonic Energy (Thailand) Co., Ltd.

- Retail/Distribution

- Consumer Goods

- Supply Chain Management

Challenge

- Total supply chain "inventory was increasing"

- "Shortages also occurred"at the site x product level

- "Inventory imbalance also occurred" among distributors

ABeam Solution

- Designing the "future supply chain model"

- Realizing "weekly production planning" process

- Applying "common inventory standards" to distributors

Success Factors

- "Reduction of total supply chain inventory" and inventory optimization at the site x product level

- Realizing "timely adjustments" for forecast gaps and market trends

- Reducing inventory imbalance and "Inventory production and supply with real market demand"

Client Challenges

Changing the mindset and building consensus among client and distributors

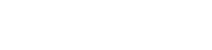

The integrated SCM process from sales to production starting from real market demand. Achieving this would require the integration of distributors in the SCM process, which had previously been managed separately by each organization. This would require not just a simple change in operations, but a change in the mindset of both client and distributors towards the fundamental aspects of their businesses, namely “procuring” and “selling,” which had never been done before. Amidst this context, the client approached ABeam Consulting, which had previously supported the transformation of the client’s back-office operations and the development of sales support app. ABeam started to support this new project from 2022.

By applying common inventory standards to distributors' inventory that had previously been managed individually by each distributor according to their own standards, and by supplying inventory to distributors in line with those standards, the entire supply chain can be smoothly linked without distortions, enabling production that meets the real market demand.

To that end, there needed to be a change in mindset on the client side, shifting away from the process ending at selling to distributors and towards focusing on maximizing distributor sales as a way of realizing the client’s own sales. On the distributor side, it was important to address the resistance towards the idea of managing inventory based on common standards designed by others, after having previously managed it based on their own standards, in order to gain the trust of the distributors towards the common inventory standards. Inventory standards are policies for balancing inventory levels and the risk of shortages. With this meaning, some distributors would see their inventory levels decrease, while others would see them increase. The Key point of this project was how to build a consensus in this regard.

The concept of future supply chain model

The concept of future supply chain model

Key Project Success Factors

Fine-tuned inventory standards and persistent dialogue with distributors

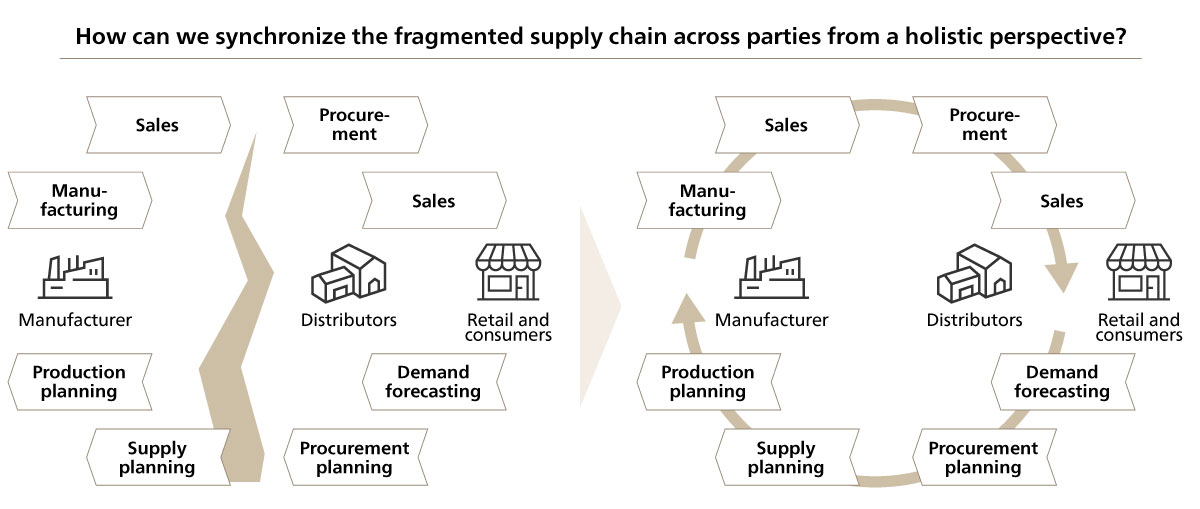

The application of common inventory standards to distributors was crucial to this supply chain model transformation. Achieving success hinged on the acceptance from distributors regarding the suitability of the inventory standards being applied.

In the process of setting the common inventory standards, ABeam Consulting aimed to produce feasible standards that balanced theory and intent. In this context, the standard inventory was reviewed and adjusted based on sales policies, after calculating initial values based on sales characteristics through statistical analysis of sales performance.

In addition, ABeam selected pilot distributors and decided the roll-out sequence and timing strategically, while also carefully communicating with distributors before and after the roll-out. In particular, ABeam drove alignment and consensus building around the approach to inventory standards with distributors that had large gaps in preferred inventory levels by continuing a regular dialogue even after the roll-out.

Thus, ABeam Consulting led the client as inventory management expert and realized optimizations to supply chain inventory all the way from the calculation of common inventory standards and subsequent verification and adjustment through to dialogue with distributors.

The approach to inventory standards and actual inventory trends

The approach to inventory standards and actual inventory trends

ABeam’s Contribution

Comprehensive support from formulating a transformation concept in line with the vision to changing the real inventory management

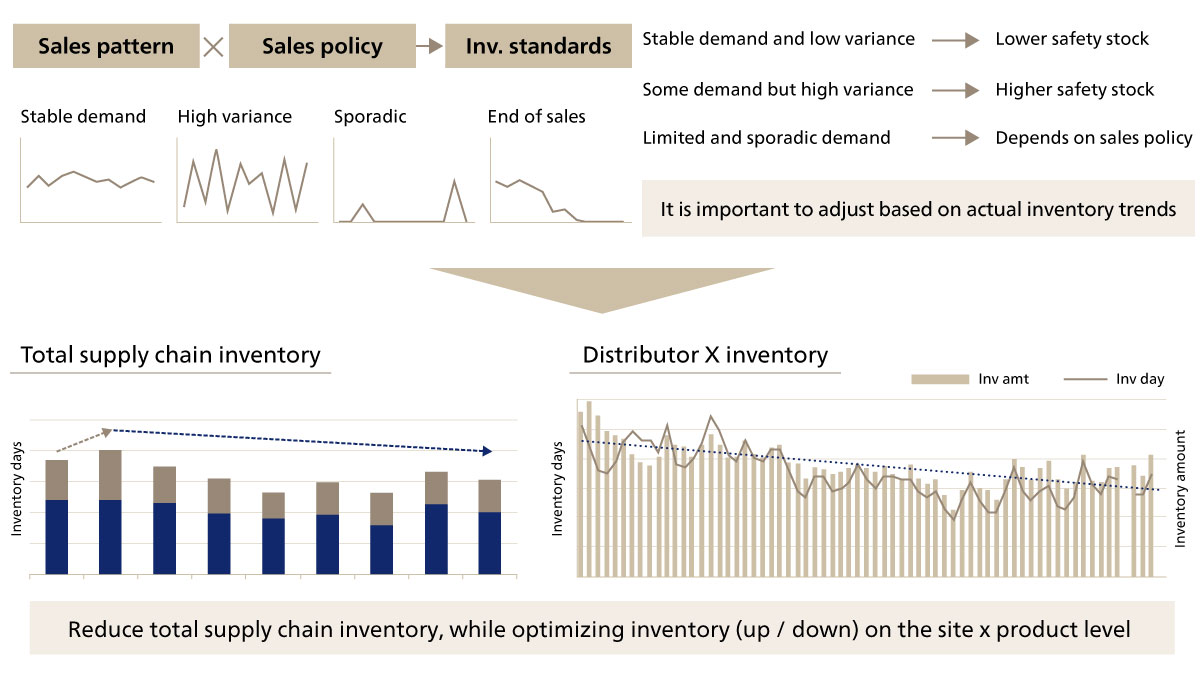

This project aimed to integrate the supply chain across the manufacturer-distributor boundaries. ABeam Consulting, as a firm with expert insights into supply chain management across both the manufacturing and retail industries, provided comprehensive support from formulating a transformation concept to the actual transformation of on-the-ground operations.

In the concept formulation phase, ABeam identified the issues and root causes based on a correct understandings of the current situation and extensive knowledge, through not only on-site interviews but also data analysis to grasp objective facts. Subsequently, ABeam engaged in extensive discussions with the client to design the future supply chain model.

In the implementation phase, ABeam further supported the consolidation of new operations by ensuring that on-the-ground operations did not disrupt inventory supply, by preparing demand and supply planning templates in line with the new operations and setting up various parameters such as safety stock and sales forecasting. As challenges and concerns emerged that were not perceived in the planning stage or that were only discovered through practical implementation, ABeam also addressed these difficulties in a timely manner by extending templates and adjusting parameters, or by deepening understanding of the new operations by continuing dialogue with for areas where we sought acceptance from partners.

By continuing such practical activities together with the client, ABeam was able to start the integrated SCM processes from sales to production starting from real market demand.

Going forward, ABeam Consulting is working side by side with the client in making efforts to improve operations to achieve further streamlining of SCM process.

The supply chain transformation flow and ABeam’s support

The supply chain transformation flow and ABeam’s support

Thanks to ABeam Consulting’s practical and persistent supports with extensive knowledge, we were able to establish a PSI (Production, Sales and Inventory) management framework starting from the real market demand, in collaboration with major customers in Thailand.

This took us a step further in improving the accuracy of sales forecasting and optimizing both our own and our customers’ inventory, challenges which we had struggled with for years. Thank you.

Panasonic Energy (Thailand) Co., Ltd.

Managing Director

Takuya Tanimoto

Customer Profile

- Company name

- Panasonic Energy (Thailand) Co., Ltd.

- HQ Location

- 166 Moo 4 Sukhumvit Road, T.Teparak A Muang Samutprakarn 10270, THAILAND

- Business

- Manufacture and sale of alkaline and manganese dry batteries

Oct 4, 2024

Click here for inquiries and consultations