Alps Alpine is supporting industry worldwide as a global manufacturer of electronic components and information devices for automotive applications. In 2010, with ABeam as its partner, Alps Electric executed the eARTHS Project to introduce a globally unified system. Subsequently, from 2020, the partners executed the WAAP Project to create synergy through management integration of Alps Electric and Alpine. From 2010 to 2023, the Global One Instance mission critical system was completed by executing these two projects. Alps Alpine aims to promote further digital transformation and achieve data-driven management based on a unified data platform.

Alps Alpine Co., Ltd.

- Global

- Data-Driven Management

- Automotive

- High Technology

Challenge

- Global standardization, simplification of management, and organizing how work is done

- Business process standardization and system integration to create synergy through business integration

ABeam Solution

- Full support for the introduction of a global mission critical system and integration from 2010 to 2023

Success Factors

- Business process standardization worldwide

- Establishment of unified data platform indispensable for promotion of DX and realization of data-driven management

Overview

Plans called for introduction of a globally integrated ERP system to review business processes

Founded in 1948, Alps Alpine Co., Ltd. is a manufacturer of electronic components and in-vehicle information equipment. Inspired by its corporate philosophy, “Alps Alpine innovates value for humans and society on a brighter planet,” the company is promoting business centering on three segments: Components, which is to be maintained and expanded as an earnings base, Sensor & Communication, which is to be expanded as a growth driver, and Module & System whose profitability is expected to be improved through qualitative enhancement of the business. Alpine, which became independent in 1978, and Alps Electric integrated their businesses in 2019. Alps Alpine conducts business operations at 186 sites in 23 countries and regions.

Prior to 2000, Alps Electric and Alpine each had its own separately operated systems. In the 2000s, Alpine was among the first companies to introduce SAP ERP, and in 2010, Alps Electric launched the eARTHS Project to introduce a globally unified system for product data management (PDM) and management of manufacturing execution systems (MES) based on SAP. Mr. Tetsuhiro Saeki, Advisor on Transformation at Alps Alpine explains: “Until the 2000s, Alps Electric had a divisional system, with each plant and division doing business in its own way. In 2008, having concluded that Alps Electric would be unable to prevail in global competition unless it changed its management strategy, the executive team decided to start by reforming the ways in which work was done.” At that time, recognizing that a thicket of time-consuming in-house processes and post-processes was holding back the company, Alps Electric was determined to change how work was done so that work with customers could proceed efficiently at a fast pace.

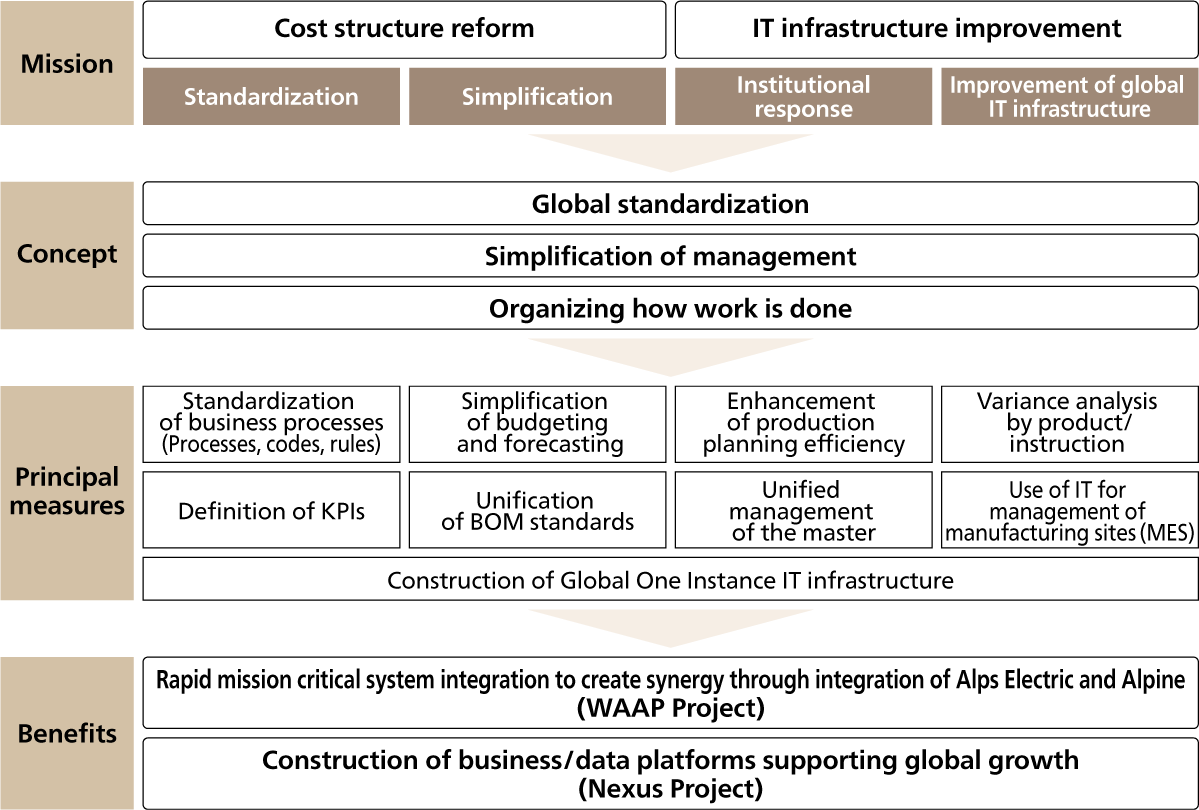

Therefore, the eARTHS Project focused on cost structure reform and IT infrastructure improvement to achieve transformation from the current status, with only limited connections between factories and divisions, to a new status characterized by global standardization, simplification of management, and a highly organized approach to the execution of work. Then, to implement effective measures, covering a shift from weekly to daily planning, unification of BOM standards, unified management of the master, unification of KPIs and codes, and IT-based management of MES at production sites, Global One Instance for globally unified management using a single system and a single database was set as the target.

“ABeam knows us very well, and so we would like to ask ABeam for continued support as we pursue various initiatives utilizing the data platform.”

Vice President, CXO

New Business & Components 1 Business

Data Solution Company

Alps Alpine Co., Ltd.

Mr. Junji Kobayashi

Why ABeam?

High-caliber expertise encompassing SAP introduction, manufacturing, and global development was the decisive factor

To realize Global One Instance, the eARTHS Project was ambitious and its scope extensive, linking not only accounting but also every process ranging from purchasing, purchase management, and production management to manufacturing execution management and sales management. ABeam was selected as the partner for SAP ERP introduction. Alps Electric partnered with ABeam because, in addition to SAP’s strong recommendation, ABeam possessed high-caliber expertise applicable to manufacturing industry as well as a wealth of experience in global development.

The eARTHS Project launched in 2010 lasted for nine years, including interruptions due to the Great East Japan Earthquake. Upon completion of the project in 2019, 61 Alps Electric sites had introduced SAP ERP, 260 systems had been replaced or decommissioned, the system was able to process 1 million orders received and 3.1 million manufacturing instructions annually, and covered 10,000 customers.

The introduction was rolled out in phases, eventually covering six regions: Japan, ASEAN, Europe, South Korea, China 1, China 2, and North America. In Japan, where introduction was most challenging, operation of the system began in April 2013 at eleven sales bases and seven factories. “Even though products were in stock, inventory data did not match physical inventory and we were unable to issue shipping instructions for certain products. At first, we didn’t know the cause, so we asked ABeam to help us clarify the problem by unraveling the connections between the parameters one by one. From this experience, we became keenly aware of the importance of enhancing data accuracy through data cleansing.” (Mr. Saeki)

Conceptually, the eARTHS Project was crystal clear: the company could not grow without global standardization. However, because there was some resistance in the field to changing the systems, the project proceeded through a top-down approach. In addition, awareness of what introduction of a globally unified system entailed was insufficient, and inadequate preparation and variations in data accuracy meant that the introduction in Japan was accompanied by a certain amount of confusion. In these circumstances, the partners forged ahead with the project without deviating from the Global One

Instance principle and ultimately achieved the targets, first and foremost standardization of business

processes and standardization and aggregation of data, including the master.

“With ABeam’s tenacious support, we were able to put our global mission critical system into operation. We eagerly anticipate ABeam’s proposals as Alps Alpine advances to the next stage.”

Advisor

Transformation

Alps Alpine Co., Ltd.

Mr. Tetsuhiro Saeki

Project goals, challenges, and solutions

With “fit to standard” as a mantra, unification with Alps Electric’s processes was rapidly accomplished

Following business integration in 2019, recognizing the need for standardization of business processes and integration of systems in order to create synergy through business integration, Alps Alpine launched the WAAP Project in 2020 to introduce a global mission critical system. The objective was to achieve multifaceted cost reduction and maximize its benefits by eliminating any duplication through unification of common business processes and consolidation of processes and systems. “In system integration, our top priority was speed. So, we proceeded through consolidation of Alpine’s mission critical system with eARTHS. In the eARTHS Project, ABeam taught us an approach that emphasized on-site work. For the introduction of eARTHS, I spent half a year visiting our sites with ABeam staff. But since the WAAP Project coincided with the COVID-19 pandemic, it was impractical to adopt such an approach,” recalls Mr. Toshihiko Akimoto, Senior Manager of the Business Process Innovation Dept. .

By prioritizing speed in promoting system introduction, Alps Alpine managed to complete the WAAP Project at 20 sites in Japan, the Americas, China, and Europe, about one-thirds of the eARTHS Project, in three years. “Given the project’s time constraints , there were some overlap as work progressed on multiple fronts. For example, we considered systematization in China while introducing the system in Japan, and then began work in the Americas while promoting the introduction in China. ABeam was at times somewhat surprised by our approach but supported us whenever issues arose that Alps Alpine people found difficult to deal with on their own. Moreover, ABeam provided comprehensive support during the tricky period when we were transitioning from the old system to the new one.” (Mr. Akimoto) Phase 1.0 of the WAAP Project was completed in November 2023 with the integration of the systems. Optimization of business processes was addressed by Phase 2.0 of the WAAP Project. Although both Alps Electric and Alpine used SAP prior to business integration, the contents of their systems were quite different, making standardization a challenge. SAP had been introduced earlier at Alpine, with each Alpine site using its own system. So, people at some sites claimed that system integration would be disruptive, but by continuing to communicate the importance of “fit to standard” (aligning business content with the system’s standard functions), the company got the sites on board and achieved system integration.

“Whenever the going became tough, ABeam always found a way forward and offered us valuable advice. We would like to continue advancing hand in hand with ABeam, our valued partner.”

Senior Manager

Business Process Innovation Dept.

Alps Alpine Co., Ltd.

Mr. Toshihiko Akimoto

eARTHS/WAAP Project Objectives and Benefits

Results and future prospects

Promote digital transformation and other measures worldwide based on the established data platform

Through the eARTHS Project and the WAAP Project, Alps Alpine introduced a global mission critical system and standardized business processes. By establishing a Global One Instance data platform, an environment was constructed allowing anyone to see all data globally at the same granularity. In the first half of the eARTHS Project, ABeam deployed its expertise in a worldwide rollout customized for Alps Electric, achieving smooth implementation. This success enabled Alps Alpine to seize the initiative in global implementation of the WAAP Project. Furthermore, promotion of Alps Alpine’s business process and system reforms with ABeam’s support has led to the development of human resources capable of promoting data-driven business process reengineering. The WAAP Project has yielded many valuable results.

“In the roughly 15 years since the launch of the eARTHS Project, priorities have changed significantly in terms of management issues, for example with the supply chain and BCP becoming higher-profile issues. Effective utilization of information is essential in this context, and the establishment of a data platform has made it possible not only for head office but also for local sites to analyze data and utilize information. This has made management far more flexible, making it possible to run the business more efficiently,” says Mr. Junji Kobayashi, Vice President CXO.

From this perspective, Alps Alpine is currently executing the Nexus Project to promote DX. One of the initiatives is to shift to more sophisticated production planning within the framework of the global supply chain. The objective is to improve the accuracy of forecasts in production planning, thereby reducing inventory and opportunity losses, eliminating dependency on individuals, and improving efficiency. ABeam provides comprehensive support from formulation of a roadmap through to construction of AI-based demand forecasting models, which are expected to improve demand forecasting accuracy by 15%.

Going forward, utilizing the global mission critical system to maximum effect, Alps Alpine will pursue company-wide DX and data-driven management to improve management capabilities through information visualization and data utilization. By doing so, the company intends to digitally connect business processes, work on capability reform and reform the cost structure so as to achieve global growth.

Customer Profile

- Company name

- Alps Alpine Co., Ltd.

- HQ Location

- 1-7, Yukigaya-Otsukamachi, Ota-ku, Tokyo

- Estd.

- 1948

- Business

- Components business, sensor & communication business, module & system business, and logistics and other businesses

- Capital stock

- 38,730 million yen

Sep 3, 2024

- Corporate data and titles are those in use at the time of writing.

Click here for inquiries and consultations