Data-driven Manufacturing for Food Factory

Data-driven Manufacturing for Food Factory

New sensing and integrated data analysis improve productivity and safety in food production, enabling Data-driven Manufacturing for new food systems.

The food manufacturing industry is facing a challenging environment due to rising raw material costs, stricter safety regulations, and changes in dietary habits. As a result, the industry is under pressure to make major changes to improve productivity, food safety, and adapt to new food systems. However, in some cases, the effectiveness of existing improvement activities and simple “digitalization” has been limited. We support the realization of digital transformation to address challenges in food manufacturing and factories by combining ABeam Consulting's expertise in smart factory and supply chain transformation in the food manufacturing industry, and YE DIGITAL's capabilities in various sensing and AI technologies.

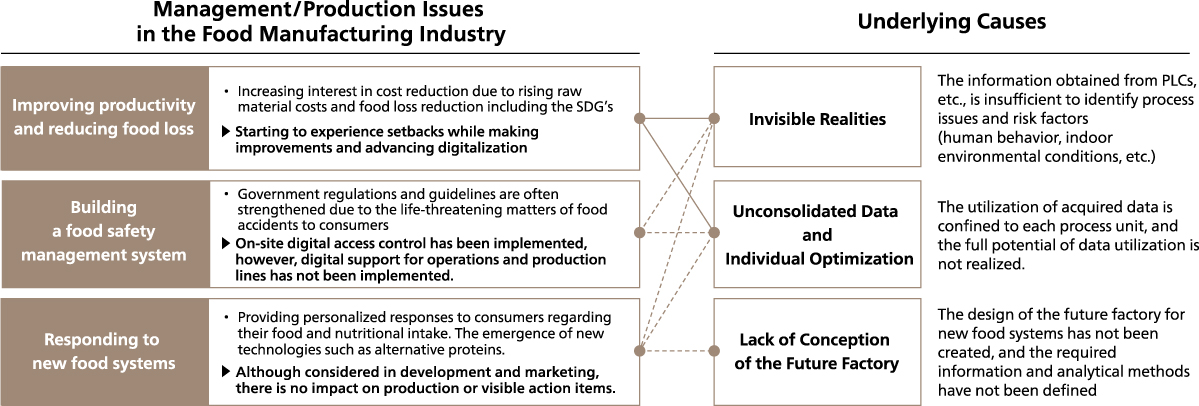

Challenges in food production and the underlying causes of the lack of initiatives on-site

The importance of improving productivity and reducing food loss, building a food safety management system, and responding to new food systems is becoming even more important. However, the management and manufacturing sites in the food manufacturing industry are struggling to find solutions through conventional improvement activities and digitalization. The causes underlying this issue include invisible realities, unconsolidated data and individual optimization, and lack of conception of the future factory.

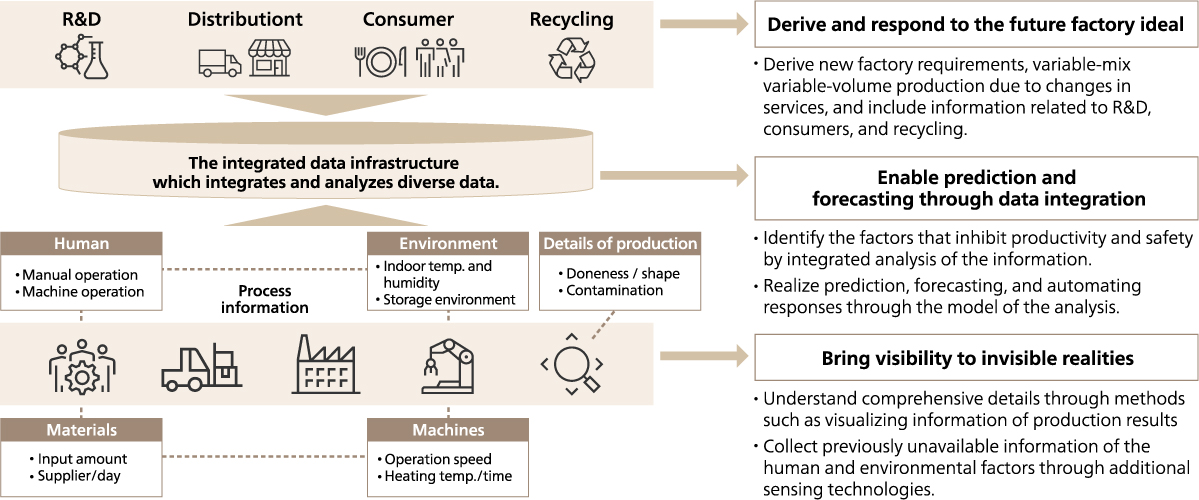

Response to the challenges and the vision to be pursued by this solution

This solution supports the continuous transformation of food manufacturing, from conception and design to digitalization and business process implementation at the manufacturing site to bring visibility to the invisible realities, achieve prediction and forecasting through data integration, and build and respond to the future factory ideal.

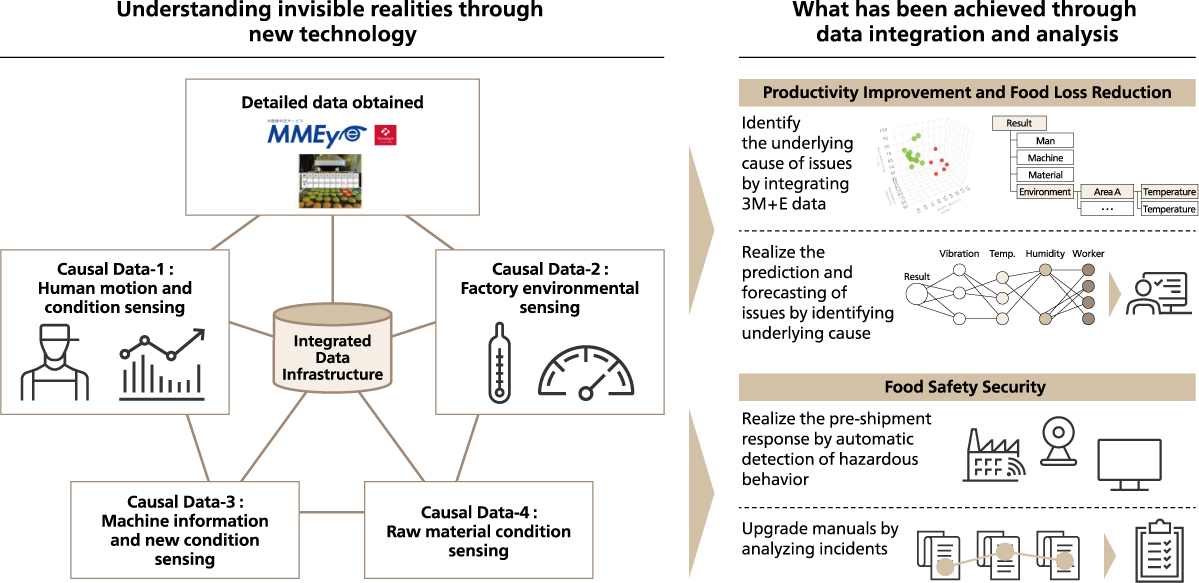

Case studies of the technologies of this solution, and its achievements

We will enhance productivity and safety in food production by leveraging new sensing and integrated data analysis technology. Specifically, we will identify and design the necessary data, taking into consideration how to acquire new data while performing data analysis and modeling, along with implementation using AI engines. This leads to solutions and operational improvements for the client’ s management and manufacturing issues.

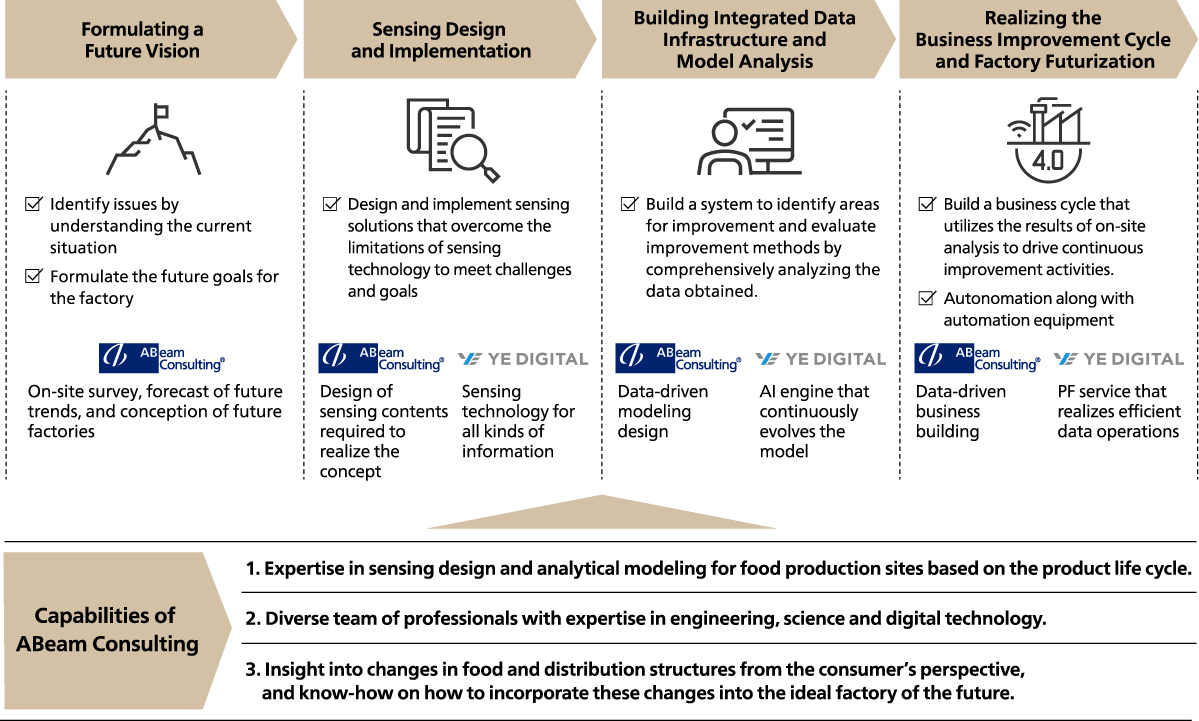

Approach and Capabilities of ABeam Consulting

We have a diverse team of professionals with expertise in engineering, science and digital technology. Additionally, we specialize in developing sensing designs and analyzing data models based on the food lifecycle. By combining this with YE DIGITAL’ s IoT and AI packages as well as their custom-building capabilities, we provide reliable support for corporate transformation, from conception and design to the implementation of cutting-edge technologies such as sensing, building an integrated data infrastructure, and business improvement.

Through integrated support, we realize data-driven manufacturing in the management and production sites of the food industry.