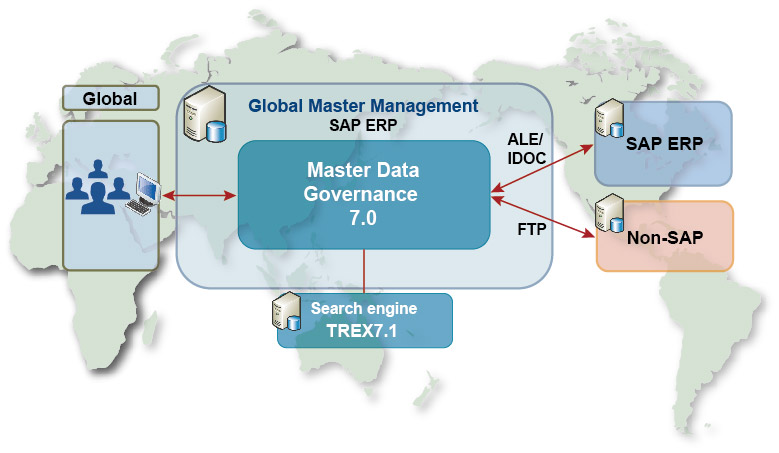

Based on its corporate message of “Enriching lives, in harmony with nature,” Kao Corporation continues to provide high value-added products and services for both consumers and business customers. Previously, each company base-located in Japan, Europe and the U.S., and Asia-managed its item masters separately; in order to strengthen its global business, Kao has now established a cloud-based, centralized system of master management.

Kao Corporation

- Process

- Health Care

- Global

- Outsourcing

Overview

Developing innovative new products through “Yoki-Monozukuri” Business expansion in Japan, Europe and the U.S., and Asia

Kao Corporation (hereinafter “Kao”) bases its business activities on the idea of “Yoki- Monozukuri” from the perspective of consumers and customers, and helps enrich the lifestyles of people globally. Through its research and development, the company engages in the creation of innovative products, which can be used safely and with peace of mind and are renowned for their high quality. Kao aims to produce and distribute these products in an efficient manner, identify consumer needs, clearly communicate the benefits of its products, and create points of sale where they can be easily chosen and bought.

Based on its corporate philosophy-known as the Kao Way-outlined above, the company is growing its business in Japan, Europe and the U.S., and Asia. For general consumers, its Beauty Care Business provides cosmetics, skin care and hair care products; its Human Health Care Business provides functional health beverages and sanitary products; and its Fabric and Home Care Business provides laundry detergents and house cleaning products.

For industrial customers, its Chemicals Business provides a diverse range of industrial products according to the needs of a wide range of industries.

In order to expand its business globally, Kao had already implemented SAP ERP for its core systems. However, since its businesses in Japan, Europe and the U.S., and Asia each possessed independent item masters, no comprehensive item master existed in which all of the Kao Group’s products were registered. ABeam Consulting (hereinafter “ABeam”) provided powerful support for Kao’s project to establish a new item master management system, with the aim of integrating the independent item masters of each region.

“ The establishment of a globally centralized item master through SAP MDG enables us to minimize implementation timeframes for new systems globally, and provides benefits such as reductions in cost and operational workloads.”

Director,Supply Chain Management Enterprise Business Excellence Enterprise Information Solutions, Global, Kao Corporation

Mr.Kenichi Kaneda

Major Issues

Centralization of master management, previously carried out independently by bases in Japan, Europe and the U.S., and Asia

Increases in the number of new products have led to depletion in the number of available item codes

Establishment of a base that anticipates the future integration of Kao’s item master with customer masters and supplier masters

Why ABeam

Continuing support, beginning with the ABS project ABeam’s familiarity with Kao’s business is highly valued

Kao chose ABeam to be its support partner for the SAP® MDG implementation project due to its experience and reliability. In October 2000, Kao initiated an ABS project which was supported by Deloitte Tohmatsu Consulting (the company which was renamed “ABeam” in November 2003).

Mr. Takanori Morizane, a member of the SCM Group in the Business Systems Department at Kao’s Information Systems Division, relates: “At that time, we felt that ABeam’s technological expertise and knowledge, as well as its ability to make proposals, was markedly superior to other companies. Since they have provided support for our systems over the long-term, they have a thorough understanding of our business. We value this highly, and this led to our choosing ABeam once again.

Indeed, what we feel now that the system has been implemented is that ABeam endeavors to see things from the viewpoint of Kao’s employees. They have faced up to various problems directly and, even in those projects which have undergone countless setbacks, ABeam has been united with us in its response. We are extremely grateful for this.”

Challenge

Core business systems were integrated via SAP ERP, but Japan, Europe and the U.S., and Asia each used independent item masters

Between October 2000 and the end of 2004, Kao executed its “Asia Business Synchronization (ABS)” project, through which SAP ERP was implemented at each of its Asian bases. This resulted in the standardization of its accounts systems and the entire supply chain-sales, distribution, production and purchasing of both consumer and chemical products.

Between 2007 and 2009, using the ABS project’s SAP ERP standardization as a template, Kao implemented SAP ERP at its Japanese bases, too; as a result, its core business systems were standardized across the world. However, while the implementation of SAP ERP allowed Kao to integrate its infrastructure, the master data used by its business systems continued to be managed independently in Japan, Europe and the U.S., and Asia.

Mr. Kenichi Kaneda, SCM manager of the Business Systems Department, part of Kao’s Information Systems Division, explains: “As the supply of various things grew globally, it became necessary to integrate our item masters, which at this time were managed independently in Japan, Europe and the U.S., and Asia.”

In addition, due to an increase in the number of products handled by the Kao Group, with the existing code length, the number of item codes was set to be exhausted in a few years. It was therefore necessary to extend the code number length as soon as possible.

Solution

In-house development of MDM, and the decision to implement SAP® MDG

Kao’s item master integration was implemented via a three-phase process. In phase one, Kao began drawing up a basic plan for an MDM system in 2007, and in 2008 started to consider which MDM system to adopt. In 2009, at the same time as it implemented SAP ERP at its Japanese bases, Kao adopted an MDM system. However, the MDM system failed to meet the company’s business requirements, and could not be effectively utilized.

Next came phase two. In 2010, Kao began a survey of its systems with the aim of independently developing an MDM system that met its business requirements. In 2011, the company defined its requirements, and considered implementing the system the following year. However, since it had already adopted SAP ERP for its core business infrastructure, Kao reconsidered whether or not it could establish a system that optimized the SAP ERP masters.

Phase three saw the trial implementation of “SAP® Master Data Governance (MDG),” SAP’s own MDM solution, which had launched with excellent timing in December 2013. Satisfied with the results of the trial, in 2014 Kao commenced its SAP® MDG implementation project and, from May to July of the same year, entered the planning stage. This included an analysis of its existing business and systems, defining its business requirements, and prototype tests. Kao subsequently conducted the implementation stage, which included system development, and unit and integrated testing, and commenced full operations in July 2015.

ABeam played an active role in the 2014 SAP® MDG implementation project, providing consistent support from initial implementation to after operations commenced. In particular, since there were no engineers at Kao with the requisite knowledge to implement the latest versions of the MDG software, ABeam has provided user-side support for the project by acting as an intermediary between Kao and SAP developers and engineers.

In addition, since Kao was the first Japanese user to implement SAP® MDG, ABeam executed a two-month planning process. It became clear that the existing version of SAP® MDG did not fulfill all of Kao’s requirements, and so it was necessary to conduct verification work for approximately one month before moving from planning to development.

Mr. Kazuya Ooshima, CE Group Leader of the Business Systems Department at Kao’s Information Systems Division, comments: “For the verification work, we invited a developer from SAP Headquarters here to Kao. Together, we went over all the specifications we were concerned about and made adjustments to the logic. This enabled us to progress problem-free to the development stage. During this time, ABeam provided extremely accurate support in relation to our correspondence with SAP Headquarters, and this allowed us to complete development verification with minimal trouble. Even after the development stage, when we encountered certain problems with the new system, ABeam’s expertise in progress management and problem management allowed us to commence operations without incident.”

Result

Key Achievements

Establishment of a rapid authorization process based on workflow systematization

Increasing the length of item code numbers, thereby resolving depletion issues

Reductions in system implementation periods and costs through the adoption of cloud services

Centralized item master management through the implementation of SAP MDG In the future, Kao intends to integrate its item master with customer masters and supplier masters

Through its implementation of SAP® MDG, Kao realized a simple item master management system that provides the ability to check master items and to guarantee its integrity with workflows, authority management, collective registration and work processes.

SAP® MDG also boasts a high affinity with SAP ERP and high compatibility with external systems, meaning that existing systems are guaranteed to work.

In addition, though Kao continued to update its item master from the 1900s, its item master data could not be easily deleted. Consequently, a great many item codes that had been registered in the past yet that were no longer in use remained in the item master.

Without re-constructing the item master and cleaning up the master data, global expansion would be difficult; for this reason, Kao’s item master was cleansed as part of the project, and the length of the item code numbers was also extended.

Kaneda says: “Before, we were unable to make changes to the item master core, so it was a complete mess. One of the benefits of implementing SAP® MDG is that we are now able to organize the item master. This, in turn, has allowed us to significantly reduce our business workloads globally.”

Previously, the Japan, Europe and the U.S., and Asia regions each had to register item codes individually, even for the same item; this meant that both the content of the item masters themselves and the way in which they were used varied from region to region. Through the implementation of SAP® MDG, Kao intends to centralize global management of item master operations.

The use of cloud services allows the system’s establishment timeframe-from procurement to implementation, establishment, operation and maintenance-to be reduced, and is also expected to lead to reductions in cost and operational workloads.

Mr. Yasushi Hamamura, Senior Manager of Corporate Services Group Accounts, Information Technology Group and Business Systems Department, at Kao’s Information Systems Division ICT Department, notes the benefits of cloud services: “On-premise systems require server procurement, establishment at each base, implementation of business systems, and operation management for individual bases. By adopting a cloud-based system, we are aiming to centralize management of the systems in Japan, Europe and the U.S., and Asia.”

The scope of the current project was limited to the establishment of a base that allowed centralized item master management. For this reason, the benefits of the system from a business perspective will not be felt immediately. In the future, the system is expected to integrate global operations, and so facilitate the management of revenues and profits.

Regarding the future of the system, Hamamura comments: “We are considering integrating client and supplier masters through SAP® MDG and establishing a globally centralized management in the future. Our ultimate goal is to use SAP® MDG as a hub to centralize master management across Japan, Europe and the U.S., and Asia. Going forward, we very much hope to continue to reap the benefits of ABeam’s outstanding support and ability to make proposals.”

Customer Profile

- Company name

- Kao Corporation

- HQ Location

- 1-14-10, Nihonbashi Kayabacho, Chuo-ku, Tokyo 103-8210

- Estd.

- June 1887

- Business

- <Beauty Care> cosmetic products, skin care products, and hair care products <Human Health Care> food and beverage products, sanitary products, and personal health products <Fabric and Home Care> fabric care products, and home care products

- Capital stock

- 85.4 billion yen (as of December 31, 2014)

Jan 1, 2017

- Corporate data and titles are those in use at the time of writing.

Click here for inquiries and consultations