Solving Overstocking Issues in B2B Manufacturing

with BPR and Digital Transformation

January 20, 2023

Business Process Reengineering (BPR) and Digital Transformation Boost Supply Chain Efficiency, Improve Forecast Accuracy and Minimize Cash Flow Impact

Case Study on B2B Manufacturing Overstock

The COVID-19 pandemic has forced businesses around the world to adapt to sudden changes in both the supply and demand realms, as well as how internal operations are conducted. These disruptions notably affect manufacturers, suppliers, and customers within the world of B2B manufacturing, forcing industry players to carefully implement workable solutions for both the short and the long term.

In particular, overstocking has become a serious problem for manufacturers in recent years. Notoriously difficult to overcome, this common issue negatively affects both cash flow and profits at a time when most businesses can afford to lose neither.

As with other inefficiencies, the first step toward managing overstock is to gain a real understanding of the source of the problem. All areas of the supply chain, manufacturing, inventory, and sales processes should be properly assessed to reveal where and how this issue originates. From there, targeted solutions can be developed and applied to better allocate resources moving forward.

As we will see below, organizations that struggle with overstocking and other problems can greatly improve internal efficiency with the help of a professional consulting firm such as ABeam Consulting. One such client, which came to us with precisely this type of overstock issue, was soon able to successfully identify the root cause and implement a lasting solution, clearing a path for growth through the years ahead.

Background

Our client was a branch of a large multinational company specializing in value-added materials, manufacturing, and trading in Thailand. They had recently increased their inventory, which severely impacted their cash flow due to the company’s own inaccurate business forecasts. In addition, they were aiming to improve their supply chain efficiency in areas such as Customer Services and Sales.

With these issues in mind, the client contacted us to find a solution for their supply chain management process. Following a thorough inspection by our team, we found that the problem originated from their Warehouse Management System (WMS). This area was primarily responsible for their shortened cash flow and profitability due to overstocking.

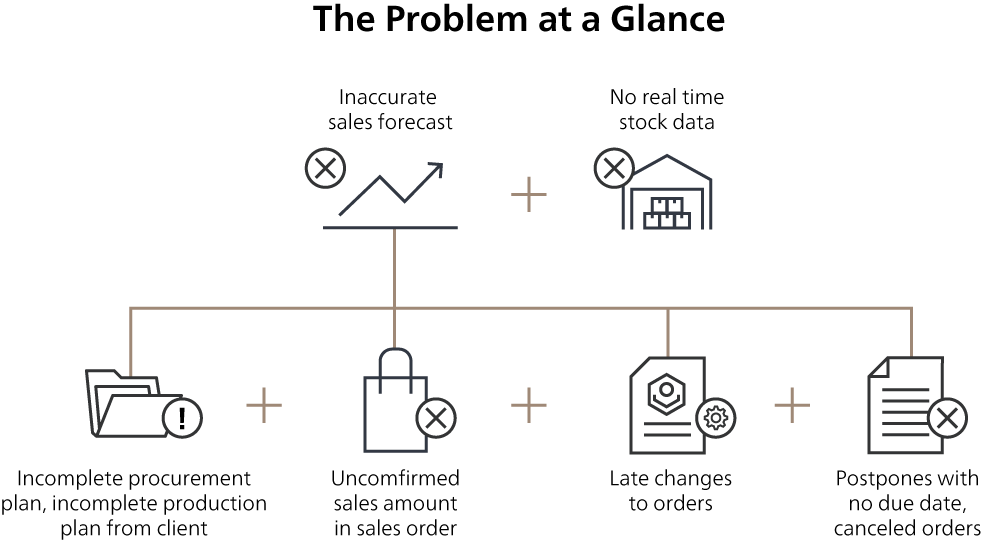

Further analysis allowed us to trace the issue back to the client’s sales forecast and purchase planning processes, which directly and indirectly caused the overstocking to take place. The main challenge was that the client lacked a centralized forecasting data system within their WMS, while also producing inaccurate stock turnover reports due to missing data. These shortcomings resulted in multiple cancellations of products whose supply materials failed to be delivered on time.

Within the order flow, the lack of accurate data from clients and a decentralized database contributed to two indirect causes of overstock. First, the absence of this data made it difficult for the Sales team to refer to past forecast information when interacting with customers. The inaccessibility of sales forecast data meant the lack of a secondary reference point, leading to uncertainty and overstock.

The second indirect issue involved the inaccurate reporting of stock turnover, due to the absence of complete and real-time data input within their WMS. This failure resulted in the lack of an inventory buffer, which was exacerbated by incorrect inventory reports from the relevant third-party warehouse. The client therefore needed to cancel some orders, or request changes to supplier purchase orders after they had been made. These irregularities reduced supplier lead time, resulting in delayed supply deliveries.

Courses of Action

ABeam Consulting proposed a variety of short- and long-term solutions in response to these issues. Our short-term solutions addressed the sales forecast challenges, and included the following courses of action:

- Cutting back on existing stock

- Improving forecast quality

These methods would be achieved by targeting the company’s top customers, who were responsible for 90% of the overstocked goods. The company would also initiate inventory reduction for the 15 materials whose total stock value was highest (together representing >50% of the total stock held by the company).

We identified the company’s key end-users, as well as the primary materials whose excessive supply represented the bulk of the overstock. From there, the company could focus on other customers from their clientele list, developing an action plan to improve forecast quality and/or reduce orders.

For long-term solutions, ABeam Consulting proposed five key improvements:

1. Centralized forecast data and stock turnover report

The lack of a centralized system for sales forecasting meant that the necessary data was not accessible by everyone. The Sales team therefore had to request data from the Customer Service (CS) team each time the need arose. Every team obtained its own forecast files, with the CS team using its own stand-alone format. Furthermore, incomplete updates to live data rendered most of the relevant information unactionable.

Our proposed solution would implement a Sales forecast system, incorporating forecasts from customers as well as the CS team. Under this arrangement, all data would be accessible by all authorized parties, with all roles and responsibilities becoming clear. The Sales team would be given responsibility for both finalizing the forecast and interacting with customers.

2. Customer contracts and agreements

Another issue we found was that customers submitted minimal or inaccurate forecast information. Furthermore, some customers did not collect the goods requested in their purchase order, or later changed the quantity of their orders. This set of problems was caused by the client wanting to improve its unique selling point for customers, to the point that it allowed limitless changes towards purchase requisitions. Unfortunately, this level of flexibility led to confusion and mismatched expectations, ultimately degrading service quality.

To resolve this situation, we suggested written improvements within certain contract clauses. These would introduce win-win solutions toward the flexibility issue, where the meeting of KPIs would trigger certain incentives such as discounts. The client's customers would therefore be motivated to send accurate forecasts without frequent purchase order changes and collect their goods on time.

3. Forecast and safety stock calculations

Reserve stock quantity had hitherto been decided by the CS team, based on individual judgment. However, this approach involved no standard set of calculations, and often led to excessive buffering. Furthermore, some relevant data tended not to be recorded, inconsistencies involving inventory planning data were evident, and the CS team kept inventory planning files in a different format than other data.

To overcome these challenges, we presented two solutions. The first was to implement a defined set of operations for forecasting purposes, which visualized both demand patterns and demand distribution, to help the client generate consistent stock forecasts within their WMS. This system would provide the Sales and CS teams with data covering historical trends and changes, customer forecast information, and safety stock requirements, for better decision-making by all teams. This inventory planning data would be stored in a common file format for ease of access.

Our next solution involved introducing a forecast function, to automatically calculate recommended order figures based on a pre-programmed model. Although this solution would require data specialists to develop calculations for each unique material, the benefits would allow the company to make arrangements for resupply orders to automatically come in, based on stock reserves and customers' forecast information.

4. Integrating a non-official sales process as a standard process

The client’s inventory was also overstocked due to non-standard planning methods. Staff members did not conform to established procedures for making sales forecasts and order creation – shortcomings which contributed in important ways to the overstocking issue.

We proposed a standard process to require any non-Sales staff member who wished to make an order, to contact the Sales team beforehand. After the Sales team verified the order with the customer, the other team members could then proceed with the authorized sales process. This process would ensure that each purchase order is properly checked, and then confirm that the materials requested are in stock.

5. Supplier lead time change updates

We noticed that sometimes the client had prepared for planned stock deliveries to arrive, only to face delays in shipment caused by their suppliers’ changing lead times – without prior notification or explanation. Moreover, the supplier often failed to inform the client of the reason behind the delay, which in turn meant that the client would pass on these delays to their customers with minimal explanation as well.

ABeam Consulting encouraged the client to be more involved with ongoing negotiations with its suppliers, with regard to clarifying and finding solutions for any delays. The supplier would also need to fill out a standardized document in case of delay, keeping the client informed about the situation. Under such a system, the CS team could confirm any prior lead time changes and take pre-emptive actions to mitigate any negative effects of a change in schedule. The client would also have enough information to provide customers with a meaningful explanation for any delays.

Implementation

We helped our client implement each of these short- and long-term solutions, combining process optimization with technology-enhanced systems.

Our inventory reduction initiatives included helping the client target the right customers and end-users for improved forecasting. By further identifying key problems, we also helped the client negotiate with all parties to solve the issue of overstock.

Next came the larger business process re-engineering phase. We split this part of the project into three further sub-stages, each utilizing a tailored approach:

- We implemented a Sales Forecasting system, using the client’s functional specifications to improve their quotation and automation capabilities.

- For non-systemic sales forecasting, we asked the client to identify key areas of interest to integrate into their agreement and identify which customers and suppliers would require discussions about lead times, documentation, and visitation.

- For lower priority issues, we offered recommendations for the client’s Specific Sales Team only.

In summary, our team discovered that the overstocking stemmed from communication and coordination issues – both within the client’s own teams, and in their interactions with suppliers and customers. To increase the level of synergy and transparency within each type of interaction, the client’s teams had to be made aware of what was going on around them, why the status quo was producing sub-optimal outcomes, and what would need to change.

We managed to solve a majority of the client’s issues by developing a centralized system that enabled the client to communicate better not only within their own teams, but also with suppliers. The relevant teams on the client’s side could now see which inquiries and orders were completed, and which situations required attention. These improvements allowed the client to better attend to their customers’ needs, and prepare swiftly for any necessary changes moving forward, thanks to their new and integrated digital platform.

Solutions for a Complex World

As organizations adjust to a post-pandemic climate of social, political, economic, and environmental change, the ability to adapt is more important than ever. Proactively implementing the right cultural and technological solutions can make this process of adaptation easier, by nipping problems in the bud or even avoiding them altogether.

Rather than waiting for new problems to appear, companies should prepare in advance by putting in place digital systems that let employees coordinate their activities – with complementary training to ensure that optimal processes are followed. These are among the best adaptations to embrace, as they have the added benefit of making all other adaptations easier to implement internally. With old staff members leaving and new one’s onboarding, having the right systems in place helps keep everyone’s responsibilities clear and on track.

Though these kinds of targeted improvements are best embraced as early as possible in each organization’s development, it is never too late for businesses to improve their operations. In our client’s case, the necessary step forward essentially involved keeping everyone – internal departments, as well as customers and suppliers – on the same page. Updated processes, re-tooled databases, and tailored software solutions all played important parts in resolving our client’s overstocking issues, although a thorough analysis was first needed to determine these courses of action.

For over 40 years, ABeam Consulting has helped with business process re-engineering, leveraging technology to solve issues across sectors – including manufacturing and supply chain problems. As a leading global consulting firm in Asia, we provide customized solutions for our clients, no matter their situation. Get in touch with us today to find out how we can help.