The Heart of Manufacturing DX

The Future of Smart Factories

Manufacturing DX Report Part 2: The State of Automation and Digitalization Responses to Manufacturing Challenges Arising from Management Changes

The Heart of Manufacturing DX

The Future of Smart Factories

Once all conquering, Japanese manufacturing is now facing structural challenges.

These come in the form of labor shortages stemming from a declining and aging population, diversification of product lineups and manufacturing variety and volume, difficulties in passing on technical skills as skilled technicians retire, and operational limitations stemming from individualization of work. They also encompass external factors in the form of decarbonization and geopolitical risks, and supply chain disruptions, and pressures over threats to the competitive edges of companies.

Given these circumstances, it seems unlikely that companies will be able to meet these challenges adequately through the one-off application of digital technologies to existing manufacturing processes in the form of visualizing processes using IoT or performing data analysis. Instead, companies face the need to build optimal solutions in the form of smart factories that can support sustainable growth over the long term and be the starting point for transformation, by combining multiple factors needed for business improvement, such as reconstruction and automation of processes.

Now is the time to combine technologies with the capabilities and strengths on the ground and lead Japanese manufacturing to the next stage.

The Growing Domain of Smart Factories

Smart factories are based on combining cutting-edge technology in the form of IoT and industrial robots, and technological elements such as AI for analyzing massive amounts of data. However, recent years have seen a growth of challenges that manufacturers need to deal with that go beyond the bounds of the factory to impact manufacturing. These include challenges in engineering chains including development and design, and coordination of supply chains in the form of procurement and logistics. Related technologies are also continuing to evolve, including automation technologies such as the spread of articulated robots and automated guided vehicles (AGVs), as well as advancements in digital twin technology.

Amidst all this, what should the “smart factory” be for your company?

Just implementing IT and digital twins, or mechanizing processes is not enough. Companies need to draw up visions for the future that include how they will deal with the external environment around factories and manufacturing, and derive what they want specifically for processes, automation, digitalization and thus their manufacturing personnel.

However, due to the breadth of scope of consideration and the number of departments that would need to be involved, at present, overall designs tend not to go as hoped. It is also the case that focus tends to fall on implementing individual IT solutions, limiting efforts to being partial optimizations.

To derive a vision for how manufacturing should work, the measures to implement that, and, by extension, the measures needed within the engineering chain and the measures needed to coordinate supply chains, all while building consensus across departments, manufacturers need commitment from their leadership class and the presence of a Real Partner to support execution.

Realizing a Vision for Manufacturing in Response to the Dramatically Changing External Environment and the Impact of Management

The starting point for addressing a changing business environment is deriving a vision for the future of manufacturing, including analysis of the circumstances surrounding each manufacturing sector and ideas around where your company wants to be. In doing so, companies need to incorporate specific process and automation designs that go beyond the drawing table, as well as the data storage and organization that underpins that.

Recent years in particular have seen dramatic developments in terms of growth in the data that manufacturers can obtain and the development of AI, on top of digitalization. There is also increasingly fertile ground for technology that can address traditionally stubborn problems such as complexity in production planning and manufacturing orders arising when making manufacturing methods or processes more flexible.

It is also important for manufacturers to develop data management practices and organizations that span departments and locations, and that go beyond the production floor. Many companies’ efforts are limited to per-department optimization. Advancing data-driven management that goes beyond manufacturing to encompass the entire engineering and supply chain serves as a foundation for improving the competitiveness of companies overall, and not just their capabilities in the manufacturing domain.

Designing Processes, Automation and Building Digital Platforms

In recent years, the manufacturing industry has seen growing diversification in product lineups and manufacturing variety and volume in response to diversification of client needs. Additionally, with challenges in the form of domestic labor shortages and the increasing retirement of experienced personnel, as well as relatively underdeveloped kaizen cultures at overseas sites and growing labor costs, manufacturers face difficulties in maintaining current manufacturing processes as they currently are.

Amidst this context, manufacturers need to ask in terms of specific design and implementation, and not on the conceptual level, what their processes should be and how they should automate operations that require manual work and human judgment based on the scope of current production volumes and product varieties, and predictions of how this will change in the future.

For example, handling the manufacturing of large product lineups with variable varieties and production volumes using existing end-to-end production lines or job-shop production is impractical and inefficient, so there are growing opportunities to consider switching to reconfigurable manufacturing systems (RMS).

At the same time, as RMS makes not only the design of processes itself but also production planning and manufacturing orders complex beyond the experience, intuition and effort of humans, implementing technologies such as AI and digital twins becomes essential. Consequently, companies need to build specific capabilities ranging from process design to the digital platforms underpinning this.

Optimization Across Entire Engineering and Supply Chains

One important element for realizing smart factories is reconstructing how R&D and design and development work. On the ground in product development in manufacturing, we often see cases where individual optimizations on the level of particular departments or teams have made progress. We also see cases where, in addition to information being fragmented across departments due to individualized data management, paper schematics and ledgers, and operations reliant on being on the ground or on experienced skilled workers prove to be barriers to transformation.

The key for companies to break out of such conditions and successfully implement next-generation manufacturing transformation is to first draw up a vision for product development in response to their businesses and goals, then to drive the use of development models that take data as their starting point by, for example, organizing operations and preparing data, and building and connecting models (i.e., data-driven development).

In advancing such efforts, it is essential for companies to make use of digital technology in the form of devising visions using digital twins and taking stock of and evaluating technology, and building databases to store knowledge through the use of AI.

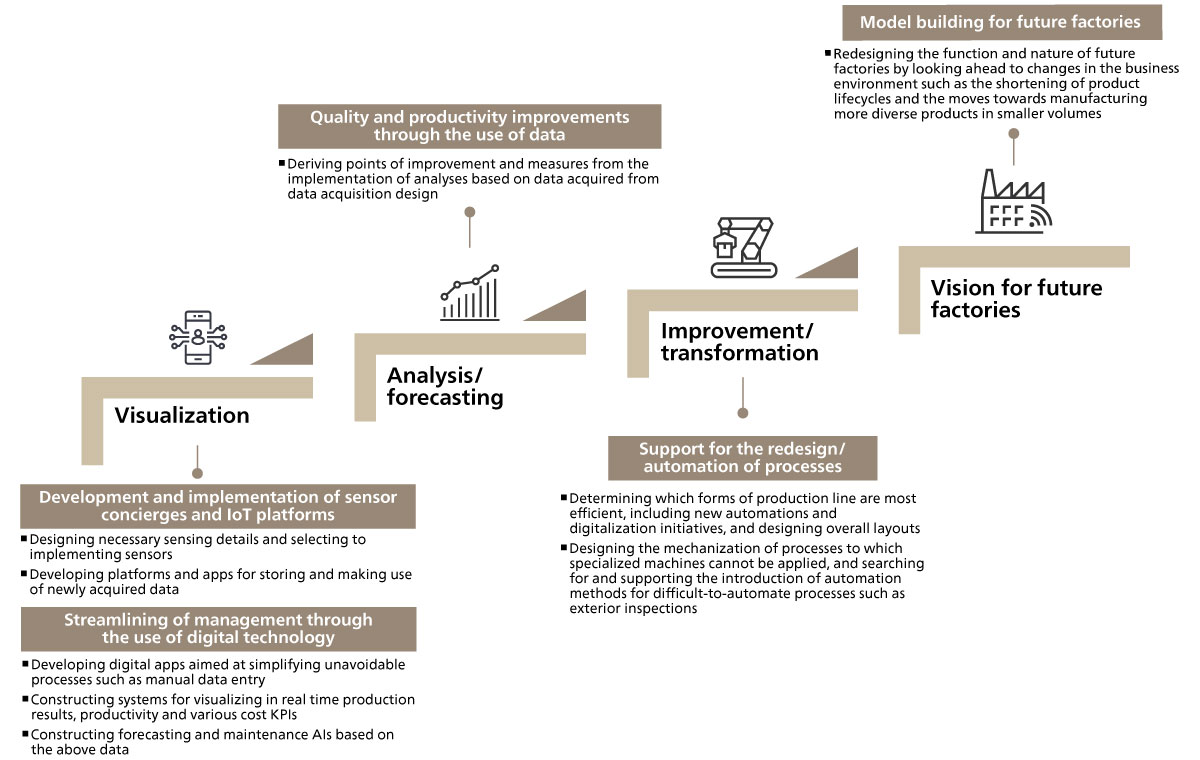

ABeam Consulting possesses the technological capabilities needed to improve and streamline manufacturing floors in order to realize smart factories.

We support engineering chain transformation in the form of design and procurement that involves transformation of manufacturing-related operations and personnel, and conversion to smart factories, using operational redesign, automation design and digitalization for addressing new challenges such as the growing diversification in product lineups and manufacturing variety and volume.

Click here for inquiries and consultations